Zbigniew Rusek wrote: This is how it is with corrosion, but e.g. a plastic pipe is easy to damage when something is punched in the wall and you do not notice the installation (it is easy to pierce it with a hammer - especially when you hit it with a large hammer).

You theorize.

So I'm going to give you one typical example of pipe drilling that I've dealt with. The tiler only had to install a toilet paper holder by the lavatory. Unfortunately, he did not remember how the pipes ran. Unfortunately, he didn't have a metal detector, but he drilled until he found it. He drilled the first hole without drilling through the pipe. The second one has already drilled successfully.

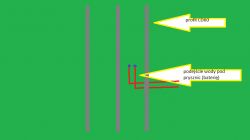

To show you what it looked like, I'm posting a photo with drawn elements that were there. Unfortunately, I don't have the original photo after forging these tiles.

As you can see, a galvanized steel pipe, drilled in two places.

The woman reached me through a mutual friend. Crying, she begged me to help her, as she and the tiler had previously called 11 plumbers who refused to do the repair, either right away on the phone, or looking at photos sent via MMS, or after seeing it on site.

An additional problem was that behind this wall was a kitchen that had been renovated. This elbow at the top was connected to the new kitchen installation made of PP pipes and it was not possible to turn it.

Fortunately, we managed to cut the tee and unscrew a fragment of the tee from this elbow. Cramming deeper to grab the pipe with a wrench was out of the question, because there was a possibility of damaging the glass on this wall located behind the renovated kitchen.

So now suggest how you would fix it. After all, you think it's a trivial job. In my opinion, this is not an easy job, which I undertook to repair as the first of twelve professionals.

Zbigniew Rusek wrote:

Besides, if the connection is not carefully welded, it may leak or leak (much depends on the accuracy of execution) and a welding machine is needed to make such a connection. Steel ones are certainly the most resistant to mechanical damage and allow for modifications of the installation without destroying it (unscrews).

What you write is not true. Removing the drilling of steel pipes is quite a breakneck task without destroying the entire wall. Unless a professional has the right equipment.

In the photos above, the pipes were quite young, because the installation was about 10 years old, because so many years ago the bathroom was renovated there. Only because they weren't old yet, the threads didn't break.

When it comes to welding PP pipes, it is not a complicated operation and unless someone is dirty and does not weld pipes dirty with grease or mortar and follows the recommendations, each connection made will be 100% tight.

It's different with steel pipes. A decent threader costs 2 thousand. PLN upwards Cheap threaders can bend pipes and damage threads, which become leaky and impossible to seal

Zbigniew Rusek wrote:

In the case of plastic pipes (PP, PEX), any modification is a problem, because the connections are not threaded, so the installation must be cut (this is destruction).

On the contrary. Repairing such damage is trivial. Forge a piece of pipe, cut it with an allowance, insert a tee and sockets, and tighten. Half an hour's work - top.

Zbigniew Rusek wrote:

Copper - theoretically, it can be desoldered and re-soldered after processing, but it is not as strong as steel (mechanical damage, e.g. caused by impact).

Copper is very difficult to solder when there was already water in it. Even the smallest droplets that flow down from time to time can cool the pipe so much that cold solders are formed, which can last for several days, and after a few days or months it will start to pour.

In this case, it is much easier to weld PP, because the pipe is thick and is a difficult heat conductor. Copper, on the other hand, is a very good conductor of heat, which is why it is so difficult to solder it when the pipe is wet inside or there is steam inside.

Added after 12 [minutes]: misio4you wrote:

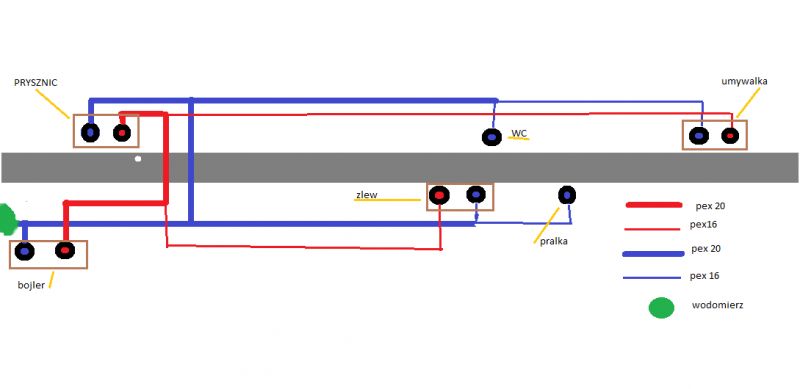

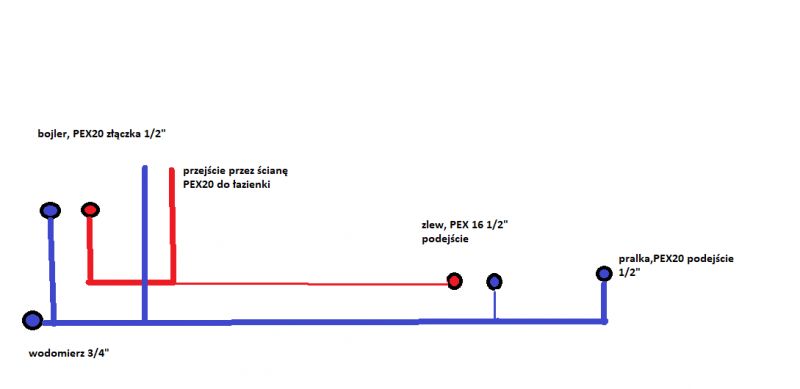

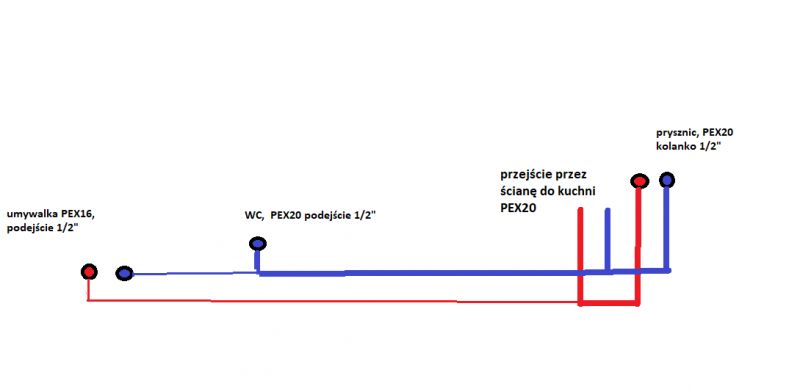

The approach to the WC and WASHING MACHINEs on PEX20 requires changes. Is there a 1/2" connection to each device? e.g. PEX20 and 1/2" output PEX16 and 1/2"?

For all 1/2" taps and valves

PEX 16 is enough for the washing machine and toilet