Hello,

I definitely need help.

I have an old "no name" transformer welder.

This welder is a device based on a welding transformer, which is wound with aluminum wire.

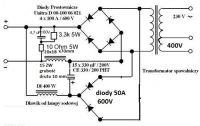

A rectifier built on four diodes has been added to the transformer outputs. Throttle missing.

Idle output voltage: 62V.

The manufacturer specifies the maximum welding current parameters at 160A.

There is little truth in this but the electrode 3.2 can somehow be welded there.

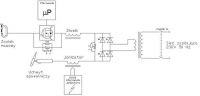

I tried to use this as a TIG source by connecting a TIG torch and of course gas (argon).

Several times I was able to initiate the bow correctly and then it was welding even cool (for someone who never had a TIG in hand).

The problem is the arc initiation. After another sticking of the electrode and damage to several electrodes, my enthusiasm subsided a little.

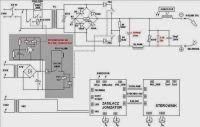

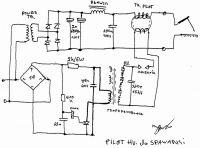

Now I have such a neat plate - a high voltage generator from the Flora Dekatech TIG130 inverter.

Does anyone have a scheme to control such a generator? (I mean the value of the supply voltage and frequency).

I can handle the welding output connection and protections.

I definitely need help.

I have an old "no name" transformer welder.

This welder is a device based on a welding transformer, which is wound with aluminum wire.

A rectifier built on four diodes has been added to the transformer outputs. Throttle missing.

Idle output voltage: 62V.

The manufacturer specifies the maximum welding current parameters at 160A.

There is little truth in this but the electrode 3.2 can somehow be welded there.

I tried to use this as a TIG source by connecting a TIG torch and of course gas (argon).

Several times I was able to initiate the bow correctly and then it was welding even cool (for someone who never had a TIG in hand).

The problem is the arc initiation. After another sticking of the electrode and damage to several electrodes, my enthusiasm subsided a little.

Now I have such a neat plate - a high voltage generator from the Flora Dekatech TIG130 inverter.

Does anyone have a scheme to control such a generator? (I mean the value of the supply voltage and frequency).

I can handle the welding output connection and protections.