Hello,

I have a drill made by DDR Smalcalda and when I got it, it turned out that there are brushes to replace. Not because of wear, but simply one that burst and the cable fell off. I bought brushes 6x6 [mm] and after assembly they caught the attention of sparking on the brushes. I am not able to say for sure if such sparking is a cause for concern.

I noticed some facts that may affect this behavior:

1. The new brushes are profiled at the ends to a round commutator (which I think is a big plus) but the part that connects to the commutator is not smooth, but it still has small fringes, can it reach? Because of this, it does not adhere exactly to the commutator. If this can cause such a problem, I can always try to grind them on but I do not know if I can keep the shape adapted to the round commutator.

2. The new brushes are as if "less" carbon, that is, the old ones were black, as if all made of carbon, and the new ones probably have some larger admixture of copper dust you can see it by color.

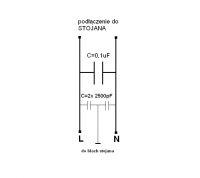

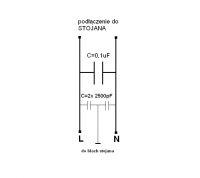

3. The capacitor on the power supply is quite bad and quite strange at all. The inscriptions on it, unfortunately, not very legible I assume that it is 0.1uF. In addition, the capacitor has a tap on a metal part of the stator. I put a drawing of the capacitor and ask for information why there is an additional tap on the metal part of the stator? Is this a rather rare solution? Can the capacitor itself, which is parallel to the power supply, affect sparking, or maybe this tap on the stator dirty? Thank you for your help.

Pictures of the drill and sparks during operation:

The capacitor seems to me that it has this structure:

I have a drill made by DDR Smalcalda and when I got it, it turned out that there are brushes to replace. Not because of wear, but simply one that burst and the cable fell off. I bought brushes 6x6 [mm] and after assembly they caught the attention of sparking on the brushes. I am not able to say for sure if such sparking is a cause for concern.

I noticed some facts that may affect this behavior:

1. The new brushes are profiled at the ends to a round commutator (which I think is a big plus) but the part that connects to the commutator is not smooth, but it still has small fringes, can it reach? Because of this, it does not adhere exactly to the commutator. If this can cause such a problem, I can always try to grind them on but I do not know if I can keep the shape adapted to the round commutator.

2. The new brushes are as if "less" carbon, that is, the old ones were black, as if all made of carbon, and the new ones probably have some larger admixture of copper dust you can see it by color.

3. The capacitor on the power supply is quite bad and quite strange at all. The inscriptions on it, unfortunately, not very legible I assume that it is 0.1uF. In addition, the capacitor has a tap on a metal part of the stator. I put a drawing of the capacitor and ask for information why there is an additional tap on the metal part of the stator? Is this a rather rare solution? Can the capacitor itself, which is parallel to the power supply, affect sparking, or maybe this tap on the stator dirty? Thank you for your help.

Pictures of the drill and sparks during operation:

The capacitor seems to me that it has this structure: