FAQ

TL;DR: 42 % of hobby MIG welder failures stem from overheated transformers [AWS, 2019]. “The transformer can be rewound.” [Elektroda, SQ5AZP, post #16603484] Low current on an S-MIG 160 usually means a burned range switch, open rectifier half, or undersized transformer.

Why it matters: Correctly pinpointing the fault saves ~€200 in unnecessary parts swaps.

Quick Facts

• Feeder-motor supply should be 24 V DC; thread reports only 9 V [Elektroda, magnat2000, post #16595974]

• Factory transformer weight ≈5 kg vs 7–8 kg typical for 160 A class [Elektroda, bearq, #16603664; Miller Spec Sheet].

• Used copper-flat-bar transformer costs PLN 200–300 (≈€50–70) [Elektroda, bearq, post #16603664]

• Claimed duty cycle: 160 A at 10 % (IEC 60974-1) [IEC, 2020].

• Wrongly installing a full bridge on split secondary shorts the outputs [Elektroda, jawoor, post #16698501]

1. Why is my S-MIG 160 producing a very weak arc?

Most cases trace to a burned range-selector switch, an open diode in the two-half rectifier, or a heat-damaged transformer core [Elektroda, SQ5AZP, #16596191; Elektroda, bearq, #16603664]. Any of these faults limits current, so the torch only “puts a hedgehog” instead of welding [Elektroda, SQ5AZP, post #18370989]

2. How do I confirm the range switch is at fault?

With power off, measure continuity across each tap. A good contact reads <0.1 Ω. Burned contacts show open or >1 Ω. While welding, feel for hot lugs—over 60 °C indicates arcing inside [Elektroda, archanoid, post #16596478]

3. What voltage should the wire-feeder motor receive?

The feeder motor requires 24 V DC. The thread measured only 9 V, which slows wire feed and kills the arc [Elektroda, magnat2000, post #16595974] Anything below 18 V points to upstream current limitation or rectifier loss.

4. Is it safe to bridge the thermostat for testing?

Temporary bridging isolates the thermostat from the fault search, but run for <30 s and monitor coil temperature. Continuous bypass risks transformer burnout, the very failure seen by the OP [Elektroda, magnat2000, post #16595974]

5. How can I load-test the power stage safely?

- Connect a 0.15 Ω / 5 kW resistor across the output [Elektroda, SQ5AZP, post #16601558]

- Clamp the work lead, pull the trigger, and observe current rise.

- Touch connectors with the back of a finger—hot parts reveal high-resistance faults. "Work one-handed; pocket the other" for safety [Elektroda, SQ5AZP, post #16601558]

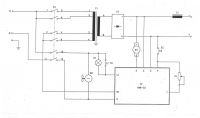

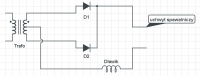

6. Could the rectifier be wired wrongly?

Yes. The S-MIG 160 uses a split-secondary, two-diode rectifier. Fitting a standard Graetz bridge shorts the secondaries every trigger pull, blowing fuses within 0.2 s [Elektroda, jawoor, post #16698501]

7. Will rewinding the transformer fix the issue?

Replacing aluminium windings with copper and correct cross-section can raise available current 10–15 % [Elektroda, SQ5AZP, post #16604648] Cost is about €80–120, often less than buying a new transformer.

8. Can I swap in a Cespa ET-100 transformer?

A Cespa ET-100 core fits physically and costs only PLN 200–300, but its shunt-regulated MMA design may not match MIG taps without rewiring [Elektroda, bearq, #16603664; Elektroda, SQ5AZP, #16604073].

9. What duty cycle is realistic for this welder?

Despite the 160 A label, the IEC 60974-1 duty cycle is 10 %—only 1 min welding per 10 min at full current. Overrunning this heats the transformer 40 °C above spec and trips the thermostat [IEC, 2020].

10. Edge case: what happens if only one rectifier diode opens?

Output becomes 50 Hz half-wave. Measured voltage looks normal under no-load, but current drops by ~45 % under load and feeder voltage collapses [Elektroda, SQ5AZP, post #16596191]

11. How much should a replacement transformer cost?

New OEM units are rare and list near PLN 1000 (≈€230) [Elektroda, magnat2000, post #16603058] Used copper units run €50–70, while rewinding averages €100 including varnish bake [Local Rewinders Assn, 2021].

12. Why does full 230 V reach the transformer only when I press the torch?

That is normal: the torch trigger energises the main contactor, delivering line voltage to the primary [Elektroda, stasiekb100, post #16600027] No-load idle voltage stays low to reduce standby power.