Hello

I am asking for help and a diagram of the best solution.

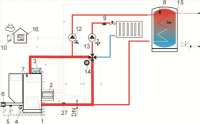

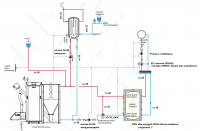

I now have a floor heating with AFRISO ATM366 thermostatic valve mixing valve with grundfos upm3 pump, bypass.

In the house there will be only a 12 floor circulator of approx. 1050m pipe, 16 house approx. 200m2 with an attic.

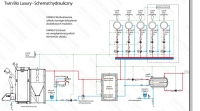

It will be supplied from the kiln pellet Kostrzewa TWIN BIO LUXURY 16 kw

In addition, the system is to be a hot water tank of approx. 250L

I would like to be able to heat independently hot water, but also that it would be possible to put a floor heating floor back on.

I wonder how to do it with the 3d or 4d valve.

I do not know the installation completely so please be understanding. The installer will probably be connected, but I would like to be able to confront his vision with your solutions.

I am asking for help and a diagram of the best solution.

I now have a floor heating with AFRISO ATM366 thermostatic valve mixing valve with grundfos upm3 pump, bypass.

In the house there will be only a 12 floor circulator of approx. 1050m pipe, 16 house approx. 200m2 with an attic.

It will be supplied from the kiln pellet Kostrzewa TWIN BIO LUXURY 16 kw

In addition, the system is to be a hot water tank of approx. 250L

I would like to be able to heat independently hot water, but also that it would be possible to put a floor heating floor back on.

I wonder how to do it with the 3d or 4d valve.

I do not know the installation completely so please be understanding. The installer will probably be connected, but I would like to be able to confront his vision with your solutions.