You are wise, and you don't know much ... Don't you know the difference? Then do as you see fit, it's your money and installation. The calvis system has no or very limited circulation in the event of a power failure with a hot boiler.

The Laddomat and the Nilsan system work identically in terms of mixing and flows, otherwise how else would it work?

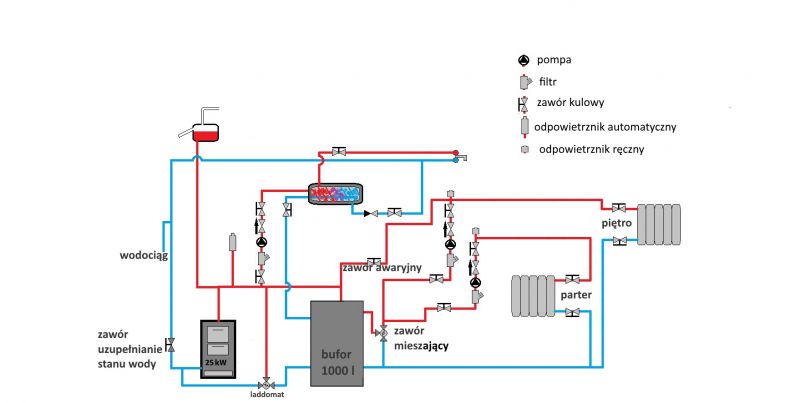

During the heating up phase of the buffer in the laddomat, natural circulation occurs through the pump (although it is turned off) and heat is transferred to the extinguished or cooling boiler. In the system I am talking about, the pump is placed high on the level of the top of the boiler and we have a siphon effect and no circulation.

In addition, you can use any pump (energy-saving electronic), not the older generation that was installed by the manufacturer and period. There is of course a version with such a pump, but the price ???

The thermostatic insert has a constant opening temperature, and if you want to experiment with temperatures (with different opals and dew points in relation to the buffer loading speed), you have to replace and buy a new one - another cost. Here you have a smooth adjustment from 40-70 degrees on the return (I used such heads with a capillary and TS-90 herz valves with increased flow.)

The cost of the replacement system is: pump, e.g. EPCO Leszno + flare nut 300 PLN, set TS valve + head 180 PLN, flap valve 5/4 "40 PLN, filter, shut-off valves 120 PLN, 3 thermometers + tees 60 PLN (really only one is enough for return of the boiler), additional fittings, let it be a hill from PLN 100. Total PLN 800 max. and a little more work, but it is probably less important because:

seiko.36 wrote: I plan to do the installation at home myself