Quote:

W / in the links a bit no hell ...

Model control signal is not a typical PWM signal - it is a high state repeating every 20 ms and taking values between 1 and 2 ms (description e.g. here:

http://forbot.pl/blog/artykuly/elektronika/kurs-elektroniki-ii -6-signal-control-pwm-id9527 - admittedly an example on the servo but the ESC controller works on the same principle only instead of changing the deflection - it changes the engine speed from 0 to max).

Quote: Oh, so I'm starting to more or less understand what's going on, i.e. these regulators are controlled by impulses, I found a diagram on the ne555 system, maybe it would pass the exam

in the form as in the drawing - certainly not, because it is - a controller for modeling servos / regulators but rather a tester - servo position / motor speed is set by a potentiometer and you need a converter but voltage-controlled.

Quote: And I have a question whether it is possible to start the engine without building the control system

No. The regulator must receive the signal described above and will come alive.

Generally, this is first of all without electronic experience (assuming that you will even find a ready converter diagram) - excuse me but the previous questions indicate that you are a bit beginner - you have little chance to assemble and run one.

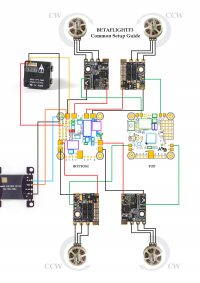

Secondly, drones use other solutions (faster - a computer drone reptile with regulators with a much faster protocol - about 10 to 50 times - than ordinary PWM).

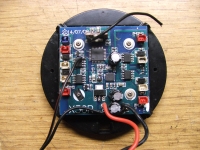

So try to make these dentures: voltage output - brushless regulator you can but how it will work - a lottery ...

So, as the previous speaker wrote - it would be good to replace the whole set, i.e. the radio - control board - regulators (the engines you bought are suitable)