FAQ

TL;DR: After mains repair, hot-water loss on Immergas Nike/Eolo Star 24 3 E is usually a clogged flow-sensor orifice; disassembly needs 2 nuts and 1 cotter pin. “100% sand-clogged.” [Elektroda, Magister_123, post #16703621]

Why it matters: This FAQ helps owners quickly restore domestic hot-water flow and decide when DIY is safe versus calling service.

Quick Facts

- Symptom pattern: cold water OK, hot water weak after debris enters system post-repair. [Elektroda, _precious_, post #16702608]

- Clogged strainers/filters cause pressure drop; some taps hide extra filters. [Elektroda, borg77, post #16702900]

- Flow sensor/orifice is the usual blockage point (“white pellet”). [Elektroda, Magister_123, post #16703621]

- Location: DHW flow sensor marked “4” on the service diagram. [Elektroda, Magister_123, post #16704341]

- Disassembly highlights: two nuts + one cotter pin; take new gaskets. [Elektroda, Magister_123, post #16704478]

Why did my hot tap water pressure drop right after street plumbing work?

Debris from the network often clogs the domestic hot water flow sensor orifice. This small “white pellet” restriction can choke hot flow while cold remains normal. An expert noted it becomes “100% sand-clogged” after such events. Clean the orifice to restore flow. [Elektroda, Magister_123, post #16703621]

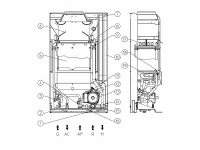

Where exactly is the flow sensor/orifice on Immergas Nike/Eolo Star 24 3 E?

On the manufacturer’s schematic used in the thread, the DHW flow sensor is indicated at position 4. Access it as shown in the shared diagram before attempting cleaning or seal replacement. [Elektroda, Magister_123, post #16704341]

How do I clean the flow sensor orifice on this boiler?

You must access the module and remove it for cleaning.

- Undo the upper nut, then the smaller rear nut.

- Pull the cotter pin and lift the assembly upward.

- Clean the orifice and reassemble with good seals.

Use new gaskets where possible. [Elektroda, Magister_123, post #16704478]

Do I need special gaskets when reassembling the flow sensor?

Yes. The upper joint uses a plain water gasket. The rear seal is typically a rubber O‑ring. Replace them if worn. If you cannot source them immediately, plan for service or a temporary workaround. [Elektroda, Magister_123, post #16704867]

What if I don’t have new seals today?

A technician in the thread reused old seals in a pinch, lubricating them with silicone grease to improve sealing. Treat this as temporary until you obtain correct replacements. “It’s easy for me” reflects skilled hands; proceed carefully. [Elektroda, Magister_123, post #16705018]

My installer didn’t fit filters before the boiler. Is that a problem?

Yes. Filters ahead of the boiler protect internal parts from grit. Missing filters increase the risk of clogged orifices and sensors after supply disturbances. The thread flags their absence as unusual practice. Install suitable inlet filtration. [Elektroda, borg77, post #16703387]

Which simple checks should I do before opening the boiler?

Clean faucet strainers at every hot outlet first. After mains work, dirt often collects there and restricts flow. If cold pressure is fine and hot remains weak after cleaning aerators, move on to the boiler’s flow sensor. [Elektroda, precious, post #16702608]

Can clogged faucet filters alone cause my hot-water pressure loss?

Yes. The thread starter found “freaky water” after supply restoration and had to clean multiple tap strainers loaded with debris. Any clogged filter introduces a noticeable pressure drop. Verify all outlet strainers. [Elektroda, borg77, post #16702900]

What tools or actions are involved to access the flow sensor?

Plan for a controlled disassembly: loosen two nuts (upper, smaller rear), pull one cotter pin, and lift the unit. Have replacement gaskets ready. This is a compact job but requires care to avoid leaks on reassembly. [Elektroda, Magister_123, post #16704478]

Is there a user-adjustable flow regulation for DHW on Eolo Star 24 3E?

A participant cleaned the fluxostat and the flow limiter yet still noticed limited simultaneous use. No adjustable DHW flow control was identified in that discussion. Capacity limits remain noticeable with two outlets. [Elektroda, kayttt, post #18466769]

Opening a wide tap drops my boiler pressure—what’s wrong?

This symptom points to an internal fault: a damaged bithermic heat exchanger or a faulty fill valve admitting water to the system. The exchanger repair may be uneconomical depending on age. Seek service assessment. [Elektroda, Magister_123, post #16893247]

When should I stop DIY and call service?

If you lack the correct seals, cannot confirm parts, or reassembly risks worse performance, call service. One user chose service rather than risk a failed reassembly. Prioritize safe, leak-free operation. [Elektroda, precious, post #16704931]

What is the “flow sensor” (fluxostat) and why does it matter?

It detects hot-water demand and meters flow through a single orifice pellet. When grit blocks this one opening, hot flow collapses though cold remains fine. Cleaning restores capacity. “100% sand-clogged” described its failure mode. [Elektroda, Magister_123, post #16703621]

What’s the typical failure edge case after cleaning everything?

If hot flow remains poor or system pressure drops when taps open, suspect a failed bithermic exchanger or a leaky fill valve. The exchanger fix can be cost-ineffective on older units. Schedule diagnostics. [Elektroda, Magister_123, post #16893247]

Do some taps hide extra filters I should check?

Yes. Certain mixer batteries include internal filters only accessible after unscrewing the body. Missing or clogged filters anywhere reduce flow and pressure at the outlet. Inspect and clean these hidden points. [Elektroda, borg77, post #16702900]

What did other users finally report as the root cause?

The thread consensus points to debris blocking the DHW flow sensor orifice after supply work. Cleaning the orifice and renewing seals restores flow in most cases. Position 4 identifies the target component. [Elektroda, Magister_123, post #16704341]