FAQ

TL;DR: Suspect feedback and protection parts first: a “silicon diode – 0.6 V drop” and a worn B5K position pot commonly cause erratic load control on the Thorn E3000. "Silicon diode – 0.6 V drop." [Elektroda, E8600, post #16755800]

Why it matters: This FAQ helps home techs quickly restore proper braking control without replacing the whole console.

Quick Facts

- Symptom snapshot: tensioner spins about 360° at power‑on; cable travel is ~2 cm, so it quickly hits limits. [Elektroda, ekler0z, post #16747969]

- Feedback device: big B5K (5 kΩ) potentiometer; a 7.6–8.3 kΩ discontinuity signals wear. [Elektroda, ekler0z, post #16747814]

- D8 SMD part: identified as a small switching diode (LL4148 form‑factor) by forum diagnosis. [Elektroda, E8600, post #16756354]

- After diode swap, intermittent faults often point to tired electrolytic capacitors in the same path. [Elektroda, E8600, post #16761103]

- Baseline tension uses a small actuator trimmer; correct set restores normal behavior after initial rotation. [Elektroda, ekler0z, post #16762451]

Why does my Thorn E3000 tensioner spin 360° when I plug it in?

That behavior means the load actuator loses position feedback, so the controller “hunts” the full range at start. Typical culprits are the big B5K potentiometer’s dead spot or a failed D8 protection/drive diode. The console may still boot and show data, yet the actuator ignores knob commands. Verify cable travel is limited (~2 cm) before testing to avoid mechanical jamming. [Elektroda, ekler0z, post #16747969]

How do I test the big B5K potentiometer correctly with a multimeter?

Disconnect one side of the pot. Measure resistance between the wiper and an end pin while turning slowly. You want a smooth sweep. A jump from 5 kΩ to about 7.6–8.3 kΩ indicates wear and will confuse the controller, causing direction flips or runaway motion. Replace if you see any discontinuity. [Elektroda, ekler0z, post #16747814]

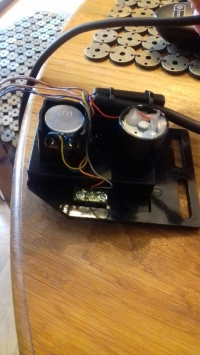

What does the small potentiometer inside the actuator do?

It is a fine‑tune trimmer that sets baseline cable tension. Set it so the cable rests within the printed min–max scale. With a good setting, the wheel may rotate once on power‑up, then the system accepts knob and program commands normally. If mis‑set, the unit can hunt or stall. [Elektroda, ekler0z, post #16762451]

The console turns on, but the tensioner ignores the knob—what should I check?

Check the panel input circuitry first. Inspect the knob’s sensor interface and the control board power path for any disturbed or failed parts. A faulty input path or missing supply rail can make the driver “think” it’s in error and refuse to move on commands. "The driver catches a bug somewhere." [Elektroda, E8600, post #16748015]

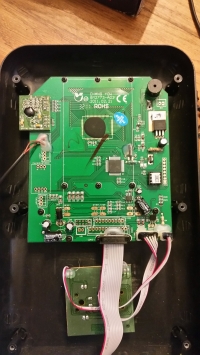

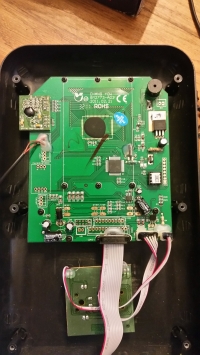

I found a chipped D8 diode. What is it and what can I replace it with?

D8 looks like a small SMD switching diode used in the actuator drive/protection path. Community identification matches LL4148‑class parts. Replace like‑for‑like, observing polarity. After replacement, re‑test actuator response and confirm no shorts on the motor lines. [Elektroda, E8600, post #16756354]

Replacing D8 fixed it for a few minutes. What’s the next suspect?

Intermittent return of the fault suggests additional stressed components. Check electrolytic capacitors in the same drive/control path and confirm the new diode’s rating suits surge conditions. Aging caps can drop supply stability, making control erratic after warm‑up. "Apparently not only the diode went down." [Elektroda, E8600, post #16761103]

Can I bypass the control board with a rocker switch to move the actuator?

Yes, users have considered a 6‑pin rocker to drive the actuator motor back/forward and reducing motor voltage from 9 V to 5 V to slow travel. This is a last‑resort workaround and removes program control and safety interlocks. Add a fuse and limit stops if you attempt it. [Elektroda, ekler0z, post #16761083]

What does “servo” mean in this elliptical’s load system?

The load mechanism is a simple servo: the controller drives a motor while reading position feedback from a potentiometer until the target tension is reached. As one expert put it, “The whole system works on the principle of servo.” If feedback is noisy, motion becomes unstable. [Elektroda, E8600, post #16747320]

How much cable travel is safe during tests?

Expect roughly 2 cm of useful travel at the magneto‑brake cable. Exceeding this risks binding or snapping the cable. If you test with the cable disconnected, watch for a full 360° motor rotation at startup, which signals lost feedback. Reconnect only after fixing feedback. [Elektroda, ekler0z, post #16747969]

The actuator reverses mid‑adjustment or moves the wrong way—what causes that?

A worn spot on the big potentiometer can feed incorrect position to the controller. When the knob passes that point, the system may command the wrong direction or oscillate. Replacing the pot and setting the small trimmer usually restores correct behavior. [Elektroda, ekler0z, post #16762451]

How do I recalibrate baseline tension after replacing parts?

Try this quick procedure:

- Set the actuator’s small trimmer so the cable sits mid‑scale at rest.

- Power on; let the wheel complete its initial rotation and settle.

- Verify the console knob steps change load smoothly end‑to‑end; tweak the trimmer slightly if the start or end sticks. [Elektroda, ekler0z, post #16762451]

What resistance should I see across the large position potentiometer?

It is a B5K device, so expect about 5 kΩ end‑to‑end. During rotation, wiper‑to‑end should change smoothly. A jump into the 7.6–8.3 kΩ region shows failure. Replace the pot to restore stable control. [Elektroda, ekler0z, post #16747814]

How can I tell if a suspect diode is silicon using my meter?

Use diode‑test mode. A typical reading near 0.6 V indicates a silicon switching diode in the forward direction. Reverse reading should be open on a good part. If the package is damaged or readings are erratic, replace it and re‑check the surrounding path. [Elektroda, E8600, post #16755800]