There are many factors that contribute to the proper functioning of the gears in a power tool. Grease. Type. How to replace. All of these factors are the problems that users encounter with gears.

What is the correct gear?

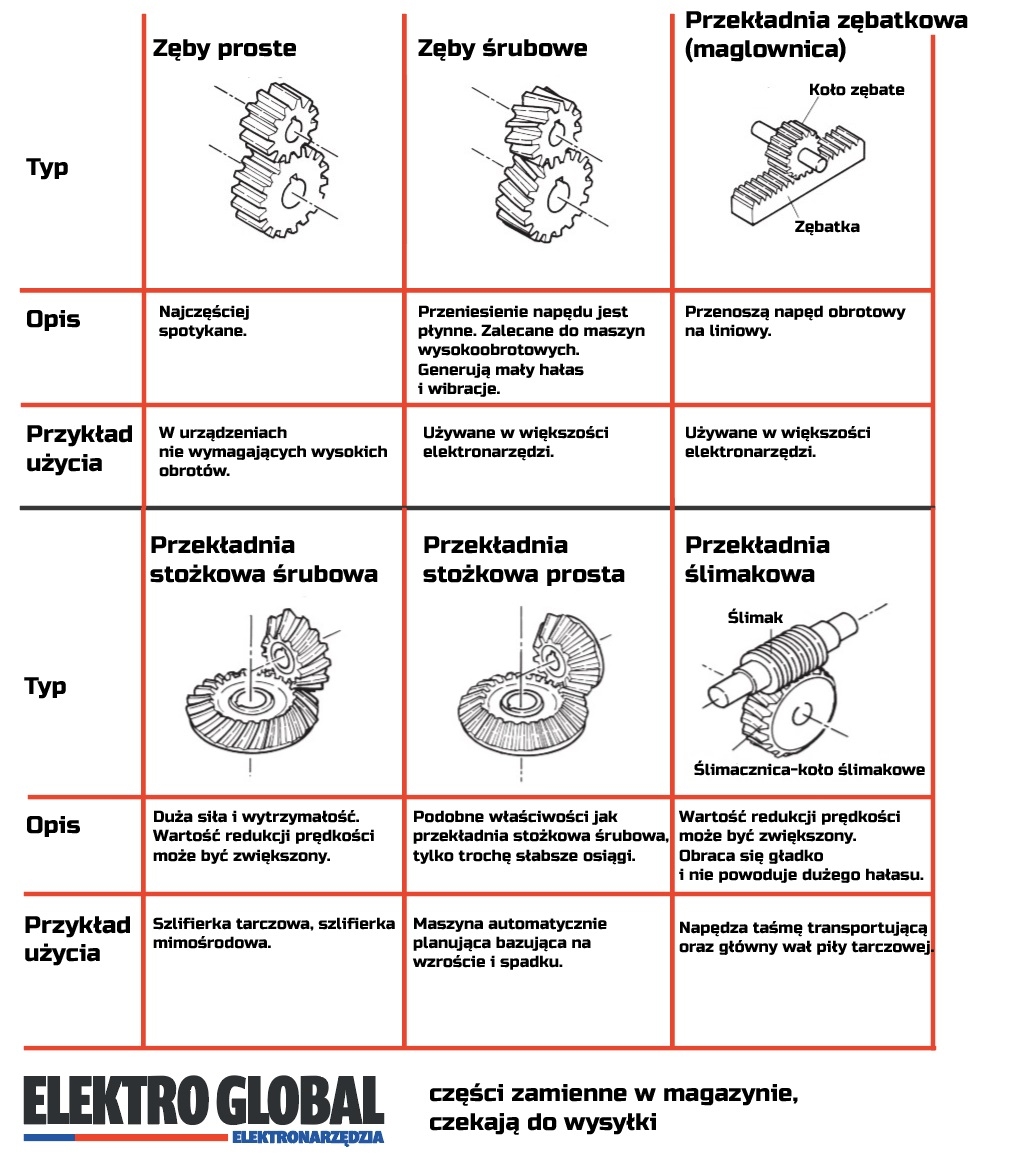

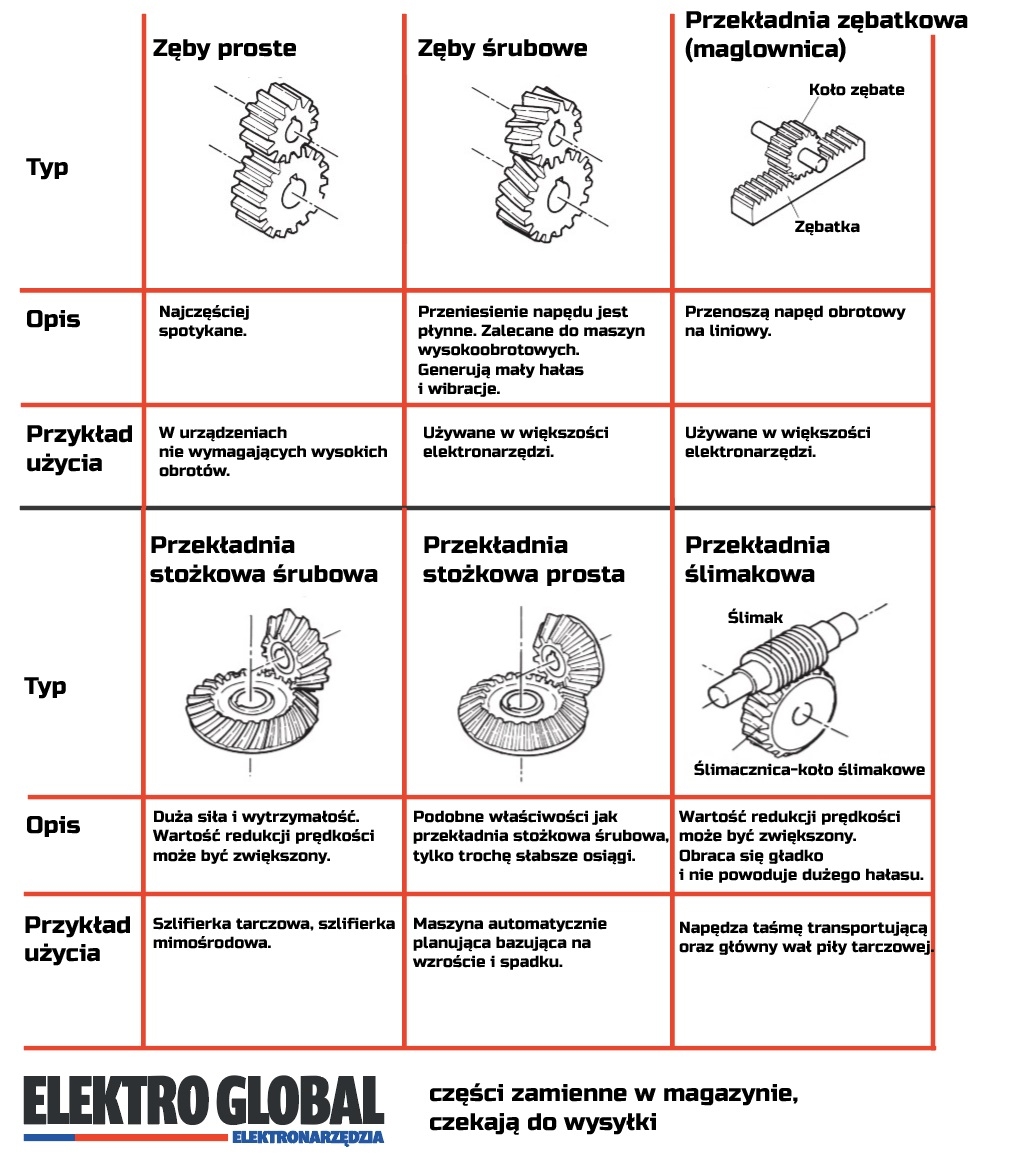

What exactly is a gear wheel. The drive, i.e. movement, is transmitted through a toothed gear. The gearbox is responsible for changing the rotation. The use of the appropriate angle and speed of the gears in the transmission enables safe transmission of power through the wheels, reducing wear and noise. This is the role of all gears, regardless of the many types. See the table below for the types of gears and their usage examples.

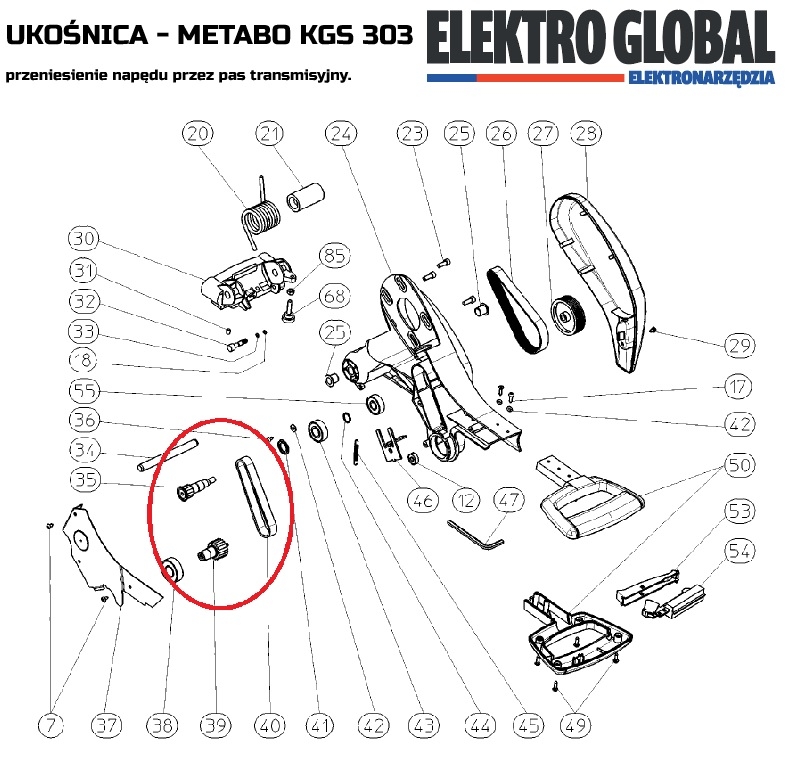

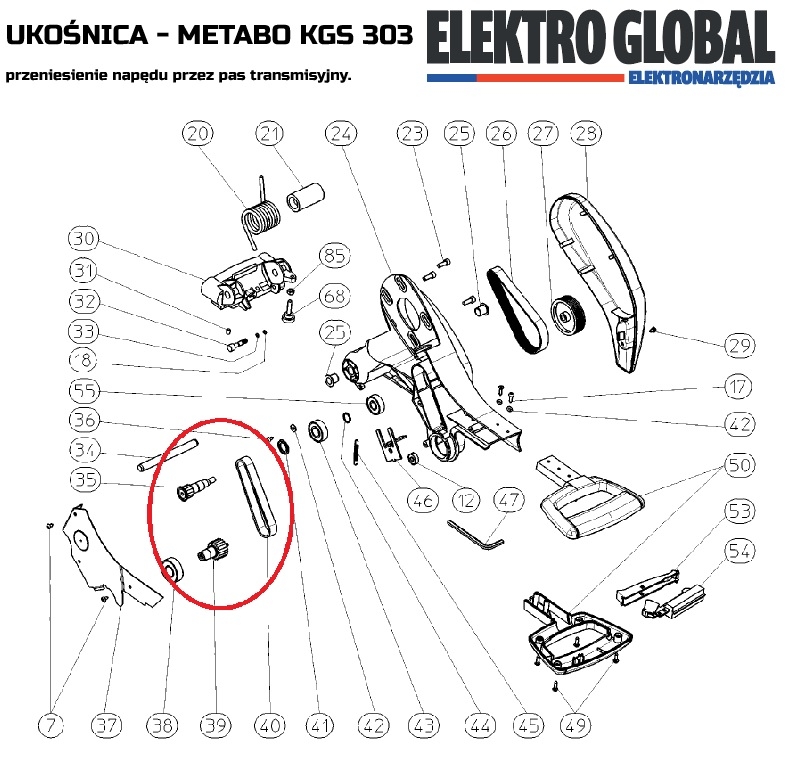

Only in some devices, such as stationary machines, for example Metabo miter saw KGS303, or an automatic scheduling device we meet the transmission of the drive through a chain or a transmission belt. In most devices, the drive is transmitted through gears.

Damaged gear? How to remove the gear?

Diagnosis of a damaged gear starts with the evaluation of the gear. How do we know that the incorrect operation of our power tool is due to gearbox damage? A damaged gear will be manifested by a characteristic "grinding" sound at work, which may result in a complete cessation of the device's operation or a decrease in rotation on the spindle. The grinding is due to the transmission slipping or slipping. How should I check for damage? The only way is to remove the chainring cover and the gear cover, which will allow us to assess the condition of our gears.

Removing the gear wheel turns out to be a common problem. The forums are full of advice on this problem. What does he really look like? Each power tool has a technical drawing , with the elements disassembled into the first parts, these drawings not only illustrate what is inside, but often show from which side we should remove a given part, e.g. our gears. Often, reading technical drawings so efficiently requires practice. Sometimes it happens that you simply do not have the skills, knowledge or use unprofessional tools. And the widely described inability to remove the gears becomes a serious problem. The gears can be secured against removal with a left-handed nut (such a nut does not unscrew during machine operation, on the contrary, it is self-tightened to the wheel by the rotational force). You will need special pliers to remove them. And another protection can be a "wedge" (the so-called half moon) it is hammered between the wheel and the axle pressed into the gear wheel. We may also encounter cases where none of these safeguards are used. Then the gear wheel on the axle is pressed on the hydraulic press after heating, the heated material expands, and thus it is pressed more easily onto the cold axle. After cooling down, the wheel, reducing its hole diameter, clamps on the axle / shaft . When we are not sure and we feel bad for our nerves, we encourage you to take advantage of service .

Grease is not equal to grease. So what kind of lubricant for the drive / gears.

Lubrication is an essential component of a power tool. The right lubricant will allow us to enjoy the life of the device for a long time. According to Mr. Ryszard, the company's service technician electro-global : " Each machine has a dedicated lubricant to use, if we use the wrong one it's like using the wrong spare part in our power tool. It happens that power tools with a damaged gear, for example, as a result of filling the pneumatic system with grease or oil that was not intended for this purpose, were already sent to the warranty service. Then such a repair is not a warranty repair. Customers often treat grease as a separate element. often on technical diagrams showing power tools the lubricant that should be purchased is given. If, for some reason, the customer needs to choose a different agent than the one he has used so far, and this happens in the case of customers who work professionally on power tools, then the selection of the lubricant must strictly comply with the manufacturer's guidelines. Such guidelines are given on the card of our machine. Manufacturers usually specify the ISO quality class, and the oil viscosity class also in the ISO standard. The selection of the appropriate spread is also entrusted to the service. The method of lubrication itself is also important, e.g. once very popular and there is still dip lubrication, but now we know as a result of many studies and observations that such lubrication causes mechanical damage such as plastic deformation of the surface of the tooth flanks, which generally do not affect the operation of the power tool but generate more noise due to increased clearances between the teeth. And here there is a risk of damage to the gear due to broken gear teeth ".

The drawing shows a damaged gear of the power tool HITACHI / / electro-global : power tools, spare parts service.

So what are the general rules for the selection of lubricants in power tools and what types do we have? In the case of power tools, a distinction is made between: lubricants for pneumatic systems, for high-speed gears, and "thicker" grease for lower speeds. And their properties are usually determinedare based on six parameters: thermal insulation, mechanical stability, oxidation, resistance to very high pressure, protection against rust, protection against water. An example of the characteristics of grease for high-speed gears used in angle grinders can be found HERE

Another important element, and often overlooked by users of power tools, is the amount of lubricant that should be applied. It is worth answering the question first: How much grease should be applied to the gearbox? Let's discuss this on the example of machines BOSCH .

example 1) In small angle grinders, e.g. GWS14-125CIE (125mm disc). Lubrication point - gear housing, lubricate the parts (gears) and fill the housing with 9-11 g. Attention! Never fill the gear chamber to full! The right grease will stick to the gears and when the machine is not running, the grease will run off - it will move due to its viscosity.

example 2) In large grinders, e.g. GWS 24-230 (230mm disc). Lubrication point gear housing lubricate the parts (gears) and fill the housing with 38-43g.

Attention! Never fill the gear chamber to full!

example 3) Electric drills - here the matter is less universal depending on how big a drill we have. With small drills, lubricate each element in the chamber and put about 6-10g of grease next to them. In more complex drills with two or three gears. Here we will have to look at the specification attached to the power tool so as not to make a mistake.

example 4) Impact hammers. Each hammer has a different specification. The lubricant should be selected so that the machine works at its maximum power, obtaining its maximum impact power, here we look at the technical specification. Too little or too much grease will result in poor impact power or no impact at all.

Gears are a naturally wearing element, but it is worth taking care of the proper operation of your device. Every power tool manufacturer, be it Festool, Hitachi, DeWALT, Milwaukee or any other, has its own specification of lubricants. It is also worth keeping the power tool documents, because they will come in handy even in seemingly mundane cases. We should also remember that highly qualified services make such additions of lubricants during the inspection of the power tool.

What is the correct gear?

What exactly is a gear wheel. The drive, i.e. movement, is transmitted through a toothed gear. The gearbox is responsible for changing the rotation. The use of the appropriate angle and speed of the gears in the transmission enables safe transmission of power through the wheels, reducing wear and noise. This is the role of all gears, regardless of the many types. See the table below for the types of gears and their usage examples.

Only in some devices, such as stationary machines, for example Metabo miter saw KGS303, or an automatic scheduling device we meet the transmission of the drive through a chain or a transmission belt. In most devices, the drive is transmitted through gears.

Damaged gear? How to remove the gear?

Diagnosis of a damaged gear starts with the evaluation of the gear. How do we know that the incorrect operation of our power tool is due to gearbox damage? A damaged gear will be manifested by a characteristic "grinding" sound at work, which may result in a complete cessation of the device's operation or a decrease in rotation on the spindle. The grinding is due to the transmission slipping or slipping. How should I check for damage? The only way is to remove the chainring cover and the gear cover, which will allow us to assess the condition of our gears.

Removing the gear wheel turns out to be a common problem. The forums are full of advice on this problem. What does he really look like? Each power tool has a technical drawing , with the elements disassembled into the first parts, these drawings not only illustrate what is inside, but often show from which side we should remove a given part, e.g. our gears. Often, reading technical drawings so efficiently requires practice. Sometimes it happens that you simply do not have the skills, knowledge or use unprofessional tools. And the widely described inability to remove the gears becomes a serious problem. The gears can be secured against removal with a left-handed nut (such a nut does not unscrew during machine operation, on the contrary, it is self-tightened to the wheel by the rotational force). You will need special pliers to remove them. And another protection can be a "wedge" (the so-called half moon) it is hammered between the wheel and the axle pressed into the gear wheel. We may also encounter cases where none of these safeguards are used. Then the gear wheel on the axle is pressed on the hydraulic press after heating, the heated material expands, and thus it is pressed more easily onto the cold axle. After cooling down, the wheel, reducing its hole diameter, clamps on the axle / shaft . When we are not sure and we feel bad for our nerves, we encourage you to take advantage of service .

Grease is not equal to grease. So what kind of lubricant for the drive / gears.

Lubrication is an essential component of a power tool. The right lubricant will allow us to enjoy the life of the device for a long time. According to Mr. Ryszard, the company's service technician electro-global : " Each machine has a dedicated lubricant to use, if we use the wrong one it's like using the wrong spare part in our power tool. It happens that power tools with a damaged gear, for example, as a result of filling the pneumatic system with grease or oil that was not intended for this purpose, were already sent to the warranty service. Then such a repair is not a warranty repair. Customers often treat grease as a separate element. often on technical diagrams showing power tools the lubricant that should be purchased is given. If, for some reason, the customer needs to choose a different agent than the one he has used so far, and this happens in the case of customers who work professionally on power tools, then the selection of the lubricant must strictly comply with the manufacturer's guidelines. Such guidelines are given on the card of our machine. Manufacturers usually specify the ISO quality class, and the oil viscosity class also in the ISO standard. The selection of the appropriate spread is also entrusted to the service. The method of lubrication itself is also important, e.g. once very popular and there is still dip lubrication, but now we know as a result of many studies and observations that such lubrication causes mechanical damage such as plastic deformation of the surface of the tooth flanks, which generally do not affect the operation of the power tool but generate more noise due to increased clearances between the teeth. And here there is a risk of damage to the gear due to broken gear teeth ".

The drawing shows a damaged gear of the power tool HITACHI / / electro-global : power tools, spare parts service.

So what are the general rules for the selection of lubricants in power tools and what types do we have? In the case of power tools, a distinction is made between: lubricants for pneumatic systems, for high-speed gears, and "thicker" grease for lower speeds. And their properties are usually determinedare based on six parameters: thermal insulation, mechanical stability, oxidation, resistance to very high pressure, protection against rust, protection against water. An example of the characteristics of grease for high-speed gears used in angle grinders can be found HERE

Another important element, and often overlooked by users of power tools, is the amount of lubricant that should be applied. It is worth answering the question first: How much grease should be applied to the gearbox? Let's discuss this on the example of machines BOSCH .

example 1) In small angle grinders, e.g. GWS14-125CIE (125mm disc). Lubrication point - gear housing, lubricate the parts (gears) and fill the housing with 9-11 g. Attention! Never fill the gear chamber to full! The right grease will stick to the gears and when the machine is not running, the grease will run off - it will move due to its viscosity.

example 2) In large grinders, e.g. GWS 24-230 (230mm disc). Lubrication point gear housing lubricate the parts (gears) and fill the housing with 38-43g.

Attention! Never fill the gear chamber to full!

example 3) Electric drills - here the matter is less universal depending on how big a drill we have. With small drills, lubricate each element in the chamber and put about 6-10g of grease next to them. In more complex drills with two or three gears. Here we will have to look at the specification attached to the power tool so as not to make a mistake.

example 4) Impact hammers. Each hammer has a different specification. The lubricant should be selected so that the machine works at its maximum power, obtaining its maximum impact power, here we look at the technical specification. Too little or too much grease will result in poor impact power or no impact at all.

Gears are a naturally wearing element, but it is worth taking care of the proper operation of your device. Every power tool manufacturer, be it Festool, Hitachi, DeWALT, Milwaukee or any other, has its own specification of lubricants. It is also worth keeping the power tool documents, because they will come in handy even in seemingly mundane cases. We should also remember that highly qualified services make such additions of lubricants during the inspection of the power tool.