Here is the patient:

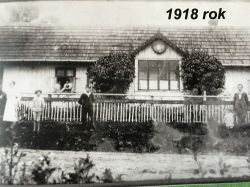

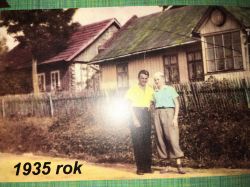

Apparently he remembers the interwar period, if not earlier, but I am not sure about the dates.

The problem is uneven gait. Sometimes it goes well and sometimes it is a minute or two late a day. After adjusting the length of the pendulum, you can start to rush.

The clock is perfectly level, on average wound up once a week. The temperature in the room is 18-22C, humidity is 50-60%. The only thing it is exposed to is the vibration of the wall when the door to the garden closes with more force (the one on the right).

Gravity doesn't play a trick either, because another shuttle ticks in the room above (from 1954 - the date is stamped there) and requires a minute adjustment every two months.

The movement was cleaned a few years ago by a watchmaker, but if necessary, I can clean it myself again, because there are no watchmakers in Scotland.

What to pay attention to, what to use to lubricate / preserve the mechanism?

Apparently he remembers the interwar period, if not earlier, but I am not sure about the dates.

The problem is uneven gait. Sometimes it goes well and sometimes it is a minute or two late a day. After adjusting the length of the pendulum, you can start to rush.

The clock is perfectly level, on average wound up once a week. The temperature in the room is 18-22C, humidity is 50-60%. The only thing it is exposed to is the vibration of the wall when the door to the garden closes with more force (the one on the right).

Gravity doesn't play a trick either, because another shuttle ticks in the room above (from 1954 - the date is stamped there) and requires a minute adjustment every two months.

The movement was cleaned a few years ago by a watchmaker, but if necessary, I can clean it myself again, because there are no watchmakers in Scotland.

What to pay attention to, what to use to lubricate / preserve the mechanism?