Ok, so my system is a Genus Premiumm Evo, with Solar In Evo System. I've one Sensys configured as Remote Control.

I've no zones defined and no zone sensors (only on/off thermostats).

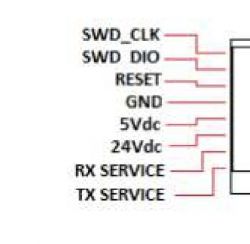

My interface is a simple optocoupler and one inverter connected to a ftdi232. No transmission interface, so I can only listen to traffic on the bus.

My raspberry runs with windows 10 core and I write the software using visual studio 17 and c #. I don't use ebusd

In this configuration, I can listen to the following messages (not all, some others I can't understand the meaning):

masters: 10 (Sensys), 33 (Solar Manager) and 38 (Burner)

10 fe 20 70 LL broadcast Date Time

10 fe 20 50 LL 55 55 or 00 00 broadcast ??? (seems a sort of counter/pace)

10 fe 20 51 LL broadcast ??? (counter + status bits?)

33 fe 20 10 LL

64 97 broadcast boiler LOW temp

6f 10 broadcast boiler HI temp

37 fe 20 0f LL

76 47 broadcast external temp

60 47 broadcast heater water temp. (floor circuit)

37 fe 20 10 LL

c0 4b broadcast heater status (01 - standby, 02 - heating, 04 - HWS, 05 - post-circulator)

61 47 broadcast HWS temp setpoint

67 97 broadcast ??? temp (always 58°C)

01 91

.....

07 91 broadcast ??? 7 params, always zeros. Zones settings?

37 fe 20 10 LL 64 97 44 02 00 65 97 44 02 00 66 97 44 02 broadcast ??? 3 parameters 9764, 9765, 9766 always 0244 (58.0°C). Could it be zones temp. set? I've no zones configured

10 38 20 00 LL 6c 10 6d 10 6f 10 70 10 solar collector(106c), boiler LOW (106d), boiler HI temps (106f) and ??? (1070) (always ff38 -20°C)

10 38 20 00 LL d1 40 6b 10 73 47 c1 00 ??? (40d1), ??? (106b), solar circulator flux (l/min)(4773) and solar circulator status (0/1) (00c1)

10 38 20 00 LL d4 showers num. and hot water tank % fill (this message appears only when I ask for solar tank status on the Sensys)

10 3c 20 00 LL 68 10 d1 40 c0 4b 0e 11 ??? always 0f (1068), floor heating circuit out (40d1), always 09 (c04b), heater status (01,02,04,05) and burner status (on/off) (110e)

10 3c 20 00 LL 75 47 c4 04 c5 46 c1 04 ??? always 0f (4775), circuit pressure (bar) (04c4), ??? (46c5) and burner power (0...255) (04c1)

10 3c 20 00 02 02 41 a5 00 -> 02 01 00 b7 ??? always 01 00

10 3c 20 00 02 02 45 a1 00 -> 02 01 00 b7 ??? always 01 00

10 38 20 00 08 03 01 03 03 c2 4b 78 47 -> 06 0f 00 00 01 00 00 7c ???

My goal was to monitor the operation of the solar system. So the Raspy collects the messages and calculates the averages every 5 minutes, then sends the results to an online web server, which then creates a daily chart.

I attach an example of a sunny day graph.

Now I'd like to make some statistics: I know when hot water is requested, I know when the burner has to start, so I can figure out how much gas is required for heating, how much for the sanitary water and how much is supplied by the solar panel.

Knowing the relative power of the boiler (0 ... 255), from Sensys I can see that the burner power is limited to 80% for heating and 67% for sanitary water. I can therefore approximately calibrate the value 0 ... 255 in KW and then in cubic meters of gas.