meriusmerius wrote: @Gabriel_Ushuaia "I have measured voltage on LM 317 (or on TBUS connector), there is 15-21V, " i've got the same readings

Can you confirm if you have this readings when the boiler is working without any errors?

I've desolder all the electrolytic and ceramic capacitors ,all the hot rezistors ,all the varistors ;measured and resolder everything back

got an error 503 (i think..was saying something about flame lift with gas valve closed ;asked me to reset..3 times in a row i got the same error ;display said to many resets).

I've

unpluged the boiler for 2 minutes ..turn it on and for some reason so far everything is working fine .

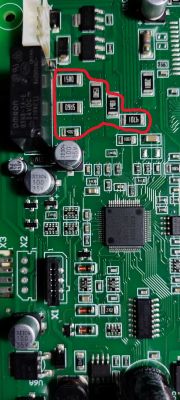

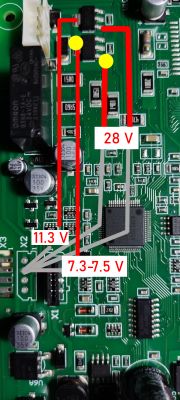

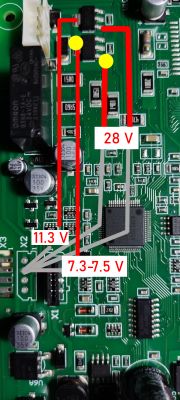

I measured what you can see in the picture...i got those value when the boiler was burning and was wondering if this is normal..

When trying to measure the voltage betwen those two yellow marks with the boiler burning I could hear the gas valve truly opening

and the gas rushing in.

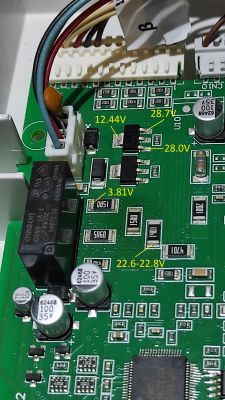

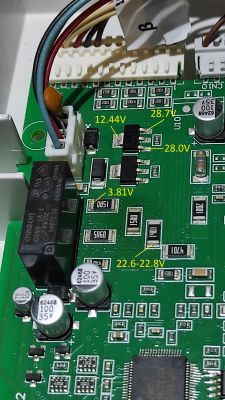

Hello, here is my mesurements when it is working, the modulating valve coil is in between the transistor collector (12.44V) and the resistor (3.81V) . So coil gets 12.44 - 3.81 = 8.63V. This is getting by the calibration process, it start increassing the coil voltage from about 7 V till the gas burns, in my case it takes 6 or 7 trys when calibrates and reach the 8.6 or 8.7V, I think the controller memorizes this state for working then, and the feedback circuit takes care of the 3.81V, the coil current (about 125mA) flows throw the two 15R0 resistors in series, and generates the 3.81V for the feedback, by the way you said the ressistors get hot and in my case too, it is because they are discipating 1/4 W each one.

I wonder if it toomuch hot and get out of tolerance and make lowering the coil current by misstake, that is a possibility of the problems, I leave it the plastic cover out and panel open and seems to work better, may be it werk not so hot, lets see.

Thanks for the comments to everyone

Regards

Added after 24 [minutes]: razorbenke92 wrote: Hi,

I have been actively reading this topic, but did not had anything to add.

This series-failure is very-very common among Hungarian users as well, and nobody knows an exact solution on any of the forums.

I have a Genus One 24 system, and I have two boards already. 1st board was damaged in a power grid failure, but before that, we already experienced errors on a monthly/bi-weekly basis. After it was replaced the errors have gone with the 2nd panel.

After one year the 2nd panel started to have the errors on the same monthly/bi-weekly basis, and after another year, it had these errors several times a day. After that I put back the 1st board (I replaced the blown varistors and capacitors) and it worked for 3-4 month, and started to get worse and worse.

I tried to replace the capacitor near the valve - did not help.

Someone said reflowing the large SMD resistors near the connector helped - for me it didn't.

I desoldered and checked all caps with ESR cap meter - every piece was giving factory values.

I came here to comment one thing about the LM317 you are suspicious about:

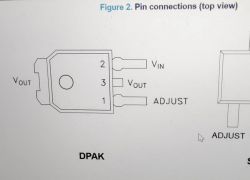

That is normal to measure changing values on that. The boiler uses a protocol called eBUS. This protocoll uses 2-wire connection which is responsible for both powering the external temp sensor, and communicating with it. It is (very briefly) communicating by changing supply voltages within a given range. This changing supply voltage is achieved by putting the LM317 into current-limiting mode. The 24V supplied by the LM7824 is going through the LM317 which is limiting the current. When the boiler/thermostat wants to say something, they short the supply voltage to ground through a resistor. As the current is limited, the supply voltage will drop, and the equipments detect this voltage drop (the dropped voltage is still way more than they require for operation).

So at least I could add this information to you, and I will stay tuned on your findings.

(There is a local electronic repair shop that says they can fix this specific panel, and they are giving warranty on it. Probably I will spend that 100Eur on it, and then I will try to backtrack what did they modify)

Hi, razor, thanks for your comments about LM317, I saw same too, it is normal working for comunication protocol, I have cube sensor connected to it, so no problems with it.

I leave it the coil parallel capacitor added and now I´ll be testing with the cover open. Rigth now I get more 309 error (about ionizzation detection) than 5P3 (flame out)

Regards