mateusz33 wrote: And I recorded the wire feeder, it shoots something but it feeds on mine smoothly

We have the culprit. It is in this video that you can see how the wire is unevenly wound. This makes welding very difficult. Especially for two-roller feeders. Four roller still can handle such a winding. He cannot grow freely, but every now and then he can be seen trapped under another scroll. Buy a wire spool, paying attention to the packaging with the information "Precision coil".

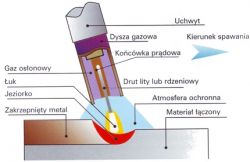

As for the welding itself, change the direction. Do not pull the handle but push it. The head on the left points towards the handle and the handle tilts to the right. The opposite situation will occur for left-handed people.

The weld will be flat first and secondly you will be able to see the place where you weld well.

The effect of boosting gas in the initial phase is typical for simple reducers. It is because of this effect that gas consumption is high. Then you will have the same gas flow and savings.

These 15 l / min is what you get for a diameter of 1.2 mm. For a 1 mm wire, reduce to about 10-12 l / min. As you noticed, the rotameter indication is different than on the reducer clock. These are all leaks in the system and for this reason the gas flow should be set on the handle and not on the reducer.

Such a small thing a matter.

As I mentioned, you can use an additional device called the optimizer or optimag.

For example, like this:

Someone will say that this is an unnecessary expense, after all, you can weld without it. Of course you can and a very large group of people are welding like this. The only question is whether it is worth considering and calculating what savings will be obtained by using this solution. You pay for gas, so maybe an expense worth considering.

This can be seen very quickly when welding in TIG. Where gas costs are not small.