FAQ

TL;DR: For WF60F4E0W0W stalls after water draw, use the 20‑minute wait—“wait 20 minutes … should show the error code”—to steer diagnosis; issues often trace to the control board. [Elektroda, Piotr2608, post #17972299]

Why it matters: This FAQ helps DIYers and technicians quickly isolate tacho vs. control‑module faults and choose the fastest safe fix.

Quick Facts

- Typical symptom: fills, quick spin, then program freezes while display stays lit. [Elektroda, mariuszkal, post #16974338]

- Fast isolation: swapping in a known‑good control panel made the washer complete a full cycle. [Elektroda, mariuszkal, post #16983023]

- Built‑in check: after it stops, wait about 20 minutes for an error code to appear. [Elektroda, Piotr2608, post #17972299]

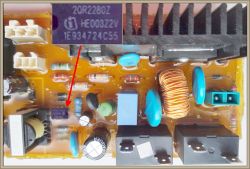

- Power stage ID: control module commonly uses ICE2QR2280Z SMPS controller. [Elektroda, TONI_2003, post #17118967]

- Field fix seen: cracked solder on the motor‑speed relay coil caused one‑direction stop; reflow restored operation. [Elektroda, marcin.s, post #19057688]

Why does my Samsung WF60F4E0W0W fill, spin briefly, then stall?

This failure pattern matches a control path issue. The washer fills, spins up, then the program halts while the display remains active. Users reported the cycle never progresses unless the control fault is addressed. Start with error-code retrieval and board checks before replacing mechanics. [Elektroda, mariuszkal, post #16974338]

What is the tachogenerator, and where is it?

The tacho is a small sensor on one side of the motor that reports drum speed. The control electronics that read it reside on the main control panel (the module behind the fascia). “Tacho is located on one side of the engine and control in the main panel.” [Elektroda, Chupacabra, post #16979425]

How can I tell if it’s the tacho or the control module?

Do a donor‑module swap test. One user connected a known‑good EcoBubble control panel; the machine then ran the entire program. Reinstalling the original panel brought the stall back. That isolates the fault to the control board rather than the tacho circuit. [Elektroda, mariuszkal, post #16983023]

How do I get the washer to show an error code after it stops?

Start a cycle and wait about 20 minutes after it halts. The washer should display an error code you can act on. As one expert put it, “wait 20 minutes … should show the error code.” Use that code to focus your repair. [Elektroda, Piotr2608, post #17972299]

Every 4–5 minutes the drum twitches faster, then nothing—what does that indicate?

That periodic twitch suggests the controller retries a motor action, then times out. One case reported a faster turn every 4–5 minutes, repeating three times, then acting like Pause was pressed. This behavior points to control logic or drive issues. [Elektroda, mariuszkal, post #16983023]

My control board is potted in gel—can I still repair it?

Yes, but access is harder. One tech noted the module was “flooded with jelly,” which obscures tracks and components. You may still replace relays or connectors, but full diagnostics and rework are slower and messier. Consider preventive relay replacement. [Elektroda, Chupacabra, post #17072735]

Can I replace ICE2QR2280Z with TNY266 on this board?

No. A contributor highlighted that ICE2QR2280Z is not the same as TNY266. They are different SMPS families and not drop‑in equivalents. If the SMPS is bad, match the original topology and ratings before replacing parts. [Elektroda, Piotr2608, post #17972299]

Could a bad relay cause the drum to move one way but not the other?

Yes. A user found a released (cracked) solder on the motor‑speed relay coil. The washer filled, moved one way, then failed to reverse. Reflowing the relay coil joints restored normal two‑direction rotation and full cycles. [Elektroda, marcin.s, post #19057688]

What’s the safest first electrical check on the control module?

Verify the power supply rails under load. One expert advised checking whether module supply voltage is correct, especially under load. If the PSU sags or is dead, logic and motor control will misbehave or stall. Measure carefully with proper isolation. [Elektroda, Pawel_P, post #17118522]

How do I isolate a board fault using a donor module?

- Disconnect power and swap in a known‑good EcoBubble control panel.

- Run a standard cycle and confirm it completes.

- Refit the original panel; if the stall returns, the original module is faulty and needs repair or replacement. [Elektroda, mariuszkal, post #16983023]

Which single component should I inspect first on a stalling unit?

Inspect and reflow the motor‑speed relay coil solder joints. A documented fix restored full function after re‑soldering that coil. Look for dull, cracked joints and heat discoloration around the relay. Replace the relay if reflow fails. [Elektroda, marcin.s, post #19057688]

Is it worth repairing this, or should I replace the machine?

If a donor control board makes a cycle complete, repair is targeted and worthwhile. Focus on the original module’s relay joints or SMPS. If the unit remains potted and inaccessible, weigh labor time against board replacement cost. [Elektroda, mariuszkal, post #16983023]