FAQ

TL;DR: PLN 950 fix solved the creamy slime in a Scania R440 XPI E5: "the compressor head was damaged" and leaking oil into coolant. Expect high cooling-system pressure and bubbles; isolate the compressor coolant loop to confirm with a simple soapy-water test. [Elektroda, Edek Edek, post #17234296]

Why it matters: For Scania R-series Euro 5 owners and fleet techs troubleshooting oil-in-coolant or retarder-linked pressure spikes, this FAQ shows fast checks to pinpoint the true source.

Quick Facts

- Confirmed fix: replacing the air compressor head solved oil-in-coolant; head ≈ PLN 950 net, new compressor ≈ PLN 2,600 net. [Elektroda, Edek Edek, post #17234296]

- Symptom cluster: creamy slime in expansion tank, high coolant pressure, cap ejecting fluid, and bubbles visible at idle. [Elektroda, Edek Edek, post #17234296]

- Pressure correlation: high pressure after retarder use over ~150 km; no pressure when retarder stayed off for ~600 km. [Elektroda, Edek Edek, post #17055858]

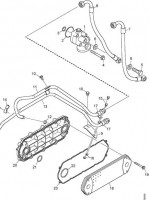

- Gearbox oil cooler check: verify gearbox oil; cooler sits right side under a cover behind the air compressor. [Elektroda, HADŻI, post #17046246]

- Case context: 2007 build, 2008 first registration, ~935,000 km at report time. [Elektroda, Edek Edek, post #17046698]

What does creamy slime in my Scania R440’s expansion tank mean?

Creamy slime indicates oil contamination in the coolant. In this case, a damaged compressor head leaked oil into the cooling system. Secondary signs were high pressure, fluid ejection on cap removal, and visible bubbles at idle. Replacing the compressor head resolved the issue. [Elektroda, Edek Edek, post #17234296]

How can I test if the air compressor head is leaking into coolant?

Use this quick isolation test:

- Bypass the compressor’s coolant circuit so coolant flows past it.

- Start the engine and keep it idling safely.

- Pack soapy water into the compressor hoses; watch for bubbling under pressure.

"Bubbles from both hoses confirmed its leakage." If confirmed, planing or replacing the head is required. [Elektroda, Edek Edek, post #17234296]

Why do people suspect the retarder cooler first?

On trucks with retarders, oil and coolant circuits meet at the retarder cooler. As one tech put it, "The only place where fluid and oil are close to each other is in the retarder cooler." That proximity makes it an early suspect during oil-in-coolant investigations. [Elektroda, darfur5, post #17046227]

Where is the gearbox oil cooler on this engine, and how do I check it?

Check the gearbox oil level first. The gearbox oil cooler sits on the right side of the engine under a cover, behind the air compressor. Inspect the cooler and lines if oil level changes or contamination appears. Access may require removing the cover and associated hardware. [Elektroda, HADŻI, post #17046246]

Can using the retarder cause the cooling system to pressurize?

In this case, yes. After using the retarder over about 150 km, the cap released high pressure when opened. When the retarder stayed off for about 600 km, no pressure appeared. That correlation helps target retarder-related heat-exchanger paths during diagnosis. [Elektroda, Edek Edek, post #17055858]

How should I check the retarder oil level—warm or cold?

Check the retarder oil warm or cold, but be consistent each time. "You must always check under the same conditions." This avoids misreading level changes during troubleshooting. [Elektroda, szaman108, post #17058961]

I lost about 1 liter of retarder oil during short use—what should I do next?

Document the drop and recheck under the same conditions. In this thread, the level fell to mid-dipstick, about 1 liter during short retarder use. Plan a leak-tightness inspection of the retarder circuit and cooler if the trend continues. Correlate findings with coolant condition and system pressure. [Elektroda, Edek Edek, post #17058543]

What signs point away from the retarder and toward the compressor head?

A tight retarder cooler test, persistent high coolant pressure, and bubbles at idle pointed elsewhere. Isolating the compressor coolant loop and observing bubbles from both compressor hoses confirmed the compressor head leak. The owner reported the retarder tested OK. [Elektroda, Edek Edek, post #17234296]

What repair attempt failed in this case?

Replacing the compressor head seals did not stop contamination. The head surface had pitting, which prevented sealing. As noted, planing the head or replacing it was required. This edge case explains recurring oil-in-coolant after a seal-only repair. [Elektroda, Edek Edek, post #17234296]

How much did the successful repair cost?

A new compressor head cost about PLN 950 net and solved the issue. The owner considered a complete new compressor at roughly PLN 2,600 net, purchased via Majorsell Skuba. Both figures reflect parts pricing at that time. [Elektroda, Edek Edek, post #17234296]

Do I need VIN-specific diagrams to identify cooler locations?

Yes, component layouts differ by VIN. A member adjusted diagrams to the truck’s VIN and noted small but important differences. Share your chassis number to get the correct layout before diagnosing coolers and lines. [Elektroda, szaman108, post #17046906]

What model year and mileage were involved here?

The truck was produced in 2007, first registered in 2008, with about 935,000 km at diagnosis. This context supports wear-related suspicion on parts like the compressor head. [Elektroda, Edek Edek, post #17046698]