I am asking for help in the correct diagnosis of the Vp-44 pump fault in my VB y22dtr. As in the topic, the solenoid valve of the injection angle adjuster (0281002173) is persistently damaged, the lower one on thinner cables. It is damaged in such a way that there is an interturn short circuit in its coil, its resistance becomes 2 ohms instead of 8-10 (This is how many valves I installed were in working order). In this state, the engine works, but after adding gas, it immediately enters the emergency mode, it is very gray, the check engine light comes on. In op-coma measuring blocks, the actual start of injection is 18.1 ° instead of the set 4.7 °. This error occurs: P1335 - "Injection Pump: No Engine Speed Input Signal From Control Module". Importantly, there is no error P0725 suggesting damage to the shaft sensor, but I replaced it anyway. It did nothing. There are also no typical errors of "falling" pump, ie: P1220, P1631, P1651 etc. I checked the wiring diagram from the engine controller to the pump controller, everything ok. After inserting a new solenoid valve, observed in blocks, the start of the injection is set and real, it is perfect cover and amount to about 4.7 °. The car drives perfectly for a period of about a week and then the solenoid valve of the adjuster is damaged again. Interestingly, the defect appears during parking or rocking in a traffic jam, and not during dynamic driving.

After consulting with experts, two completely different theories emerge. Namely:

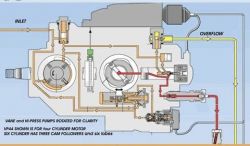

The rubbing of the adjuster piston causes that the pump controller, striving to maintain the desired injection start, "pumps" such PWM pulses onto the solenoid valve, that its coil is damaged.

The opposite theory is that even if the setting piston rubs, it still does not affect the operation of the solenoid valve and its repeated damage is caused by an unusual and irreversible damage to the pump controller (probably the 7-pin element controlling the solenoid valve).

I would like to add that when the solenoid is still ok, there are no strange symptoms while driving, even very dynamic, no interruptions, etc. I have been adding 2t oil to the fuel for a long time. The controller itself is in a revised version, i.e. the famous transistor controlling the dose adjuster goes from the board 3 wires, including 2 parallel to the source of the transistor and one to the gate. In the original, there is one each. The driver inside is impeccable. It looks like the pump was made by our western neighbors in 2003 and got a new "revised" driver. In addition, a newer soft is installed, thanks to which the glow plugs on a cold engine always heat up regardless of the ambient temperature.

What do you advise, replace the driver for 6 sts or regenerate the pump for an amount exceeding the value of the car? Have any of your colleagues encountered a similar driver fault? Because if it actually has such a "strange" fault, the regeneration of the pump mechanics may be pointless and will not improve the car.

After consulting with experts, two completely different theories emerge. Namely:

The rubbing of the adjuster piston causes that the pump controller, striving to maintain the desired injection start, "pumps" such PWM pulses onto the solenoid valve, that its coil is damaged.

The opposite theory is that even if the setting piston rubs, it still does not affect the operation of the solenoid valve and its repeated damage is caused by an unusual and irreversible damage to the pump controller (probably the 7-pin element controlling the solenoid valve).

I would like to add that when the solenoid is still ok, there are no strange symptoms while driving, even very dynamic, no interruptions, etc. I have been adding 2t oil to the fuel for a long time. The controller itself is in a revised version, i.e. the famous transistor controlling the dose adjuster goes from the board 3 wires, including 2 parallel to the source of the transistor and one to the gate. In the original, there is one each. The driver inside is impeccable. It looks like the pump was made by our western neighbors in 2003 and got a new "revised" driver. In addition, a newer soft is installed, thanks to which the glow plugs on a cold engine always heat up regardless of the ambient temperature.

What do you advise, replace the driver for 6 sts or regenerate the pump for an amount exceeding the value of the car? Have any of your colleagues encountered a similar driver fault? Because if it actually has such a "strange" fault, the regeneration of the pump mechanics may be pointless and will not improve the car.