Hello.

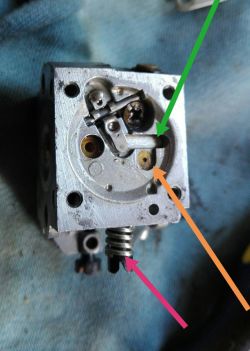

I bought "Stihl hs75" occasionally, as ex owner claimed, only the handle for the cutter was broken, but the problem was in the mixture he poured. The piston didn't just rub, it just baked. Everything cleaned, the piston works. I will add that the machine was left with fuel inside, which solidified. The problem lies in the carburetor, after thorough cleaning, what can be dismantled, because there are elements that can not be pulled out, such as this plate next to the piston / valve in the angl cup plug, the diaphragms blown channels. The carburetor does not supply fuel. I do not know if this piston is not blown out, as it is pressed, it works as if it did not want, the spring is not there anymore? What can the problem be? I will add that if it gives fuel under the candle it burns.

I bought "Stihl hs75" occasionally, as ex owner claimed, only the handle for the cutter was broken, but the problem was in the mixture he poured. The piston didn't just rub, it just baked. Everything cleaned, the piston works. I will add that the machine was left with fuel inside, which solidified. The problem lies in the carburetor, after thorough cleaning, what can be dismantled, because there are elements that can not be pulled out, such as this plate next to the piston / valve in the angl cup plug, the diaphragms blown channels. The carburetor does not supply fuel. I do not know if this piston is not blown out, as it is pressed, it works as if it did not want, the spring is not there anymore? What can the problem be? I will add that if it gives fuel under the candle it burns.