zerthimon wrote: Another question then. When does the boiler work at minimum power? How is the return temperature similar to the supply or how is the return temperature similar to that in the table, e.g. 50/30?

I don't know your boiler, so I don't know 100%.

But overall the "intelligence" of the boilers is rather simple and similar.

In my atmospheric Vaillant boiler, its work cycle is repeatable:

1.start the burner with minimum power - for me it is about 9.5kW for boiler water 80/60 - this operating mode is always maintained for the first 2 minutes after the burner starts.

The 2nd boiler switches to the intermediate power set in the boiler MENU. Intermediate power is the maximum power for what I can set it in the range from 9.5-24kW.

As my boiler is twisted to approx. 17.2kW, I can set the intermediate power in the range of 9.5-17.2kW.

Since the adjustment mechanism of the gas valve is, in my opinion, not very precise, in practice I have a displacement power with the following values:

9.5-10-12-14-16-17kW.

Currently, the indirect power on the boiler is set to 12kW, which means that after 2 minutes of operation at the starting power, the boiler switches to the 12kW operation mode.

3. If the flow temperature reaches the temperature by 2 degrees lower than the preset boiler temperature, the boiler starts modulating in the range of 9.5-12kW depending on the boiler water temperature.

Due to the low precision of the control, the power pulses.

The boiler detects the temperature by 2 degrees lower, it limits the power, but the water flow gives cooler water all the time, so lowering the power causes a temporary decrease in temperature, so as a result the boiler gives more power, because the step of changing the power is quite large, the temperature is temporarily increased and the boiler lowers power again and so on over and over again.

4. When the boiler water temperature is stabilized, the boiler works stably at its minimum power until the set temperature is reached and the burner is turned off.

Your boiler will work similarly, but it has its own operating characteristics, which I do not know, so below are my suspicions of how it can work based on my knowledge and analysis of the issue on the example of my boiler.

I assume that your boiler starts at start power X and almost immediately switches to intermediate power, i.e. the maximum power for the co-mode

Your boiler in MENU has a maximum power control, but in the range of 50-82%, and not, like mine, from minimum to maximum.

On the other hand, for domestic hot water, you can set the maximum in the range of 50-100%.

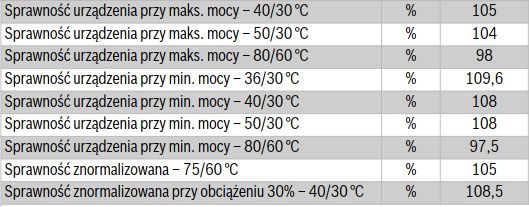

We know from technical data that for 80/60 boiler water, your boiler has a maximum of 25kW for domestic hot water and 20kW for central heating.

82% of 25kW is 20.5kW, so it fits.

This means that with the value of 82%, you have 20kW set, and with the value of 50% it will be approx. 12.5kW for the co-operation mode.

In other words, I can force my old boiler to work constantly with minimum power, regardless of the heat demand, and you can no longer force settings.

Only now, to confuse you, the minimum power can be set to 10-49%.

Assuming that after setting 10%, we get the minimum power, which according to the technical data is 4.8kW for 80/60 water, then according to arithmetic, the max should be 48kW, and as we know it is 20kW for central heating and 25kW for domestic hot water.

You also have to look at these percentages with a grain of salt.

But suppose the transition to intermediate power c.about. means work with a maximum power of 12.5 kW (80/60) after setting the value of 50% in the boiler menu.

This means that the boiler in the co mode will be able to modulate the power in the range of 4.8-12.5 kW (80/60).

My boiler starts to modulate at 2 degrees below the set value, is your boiler similar, or will it decrease only when it reaches the set temperature, I don't know, you would have to check the algorithm of your boiler's operation yourself.

Of course, the boiler can modulate earlier if it detects too much temperature rise due to e.g. limited water flow, because e.g. thermostatic heads will be too closed, etc. and continuous operation at a given moment with an intermediate power of 12.5kW will not be possible.

Let's assume that the minimum power of the boiler is reached when it gets close to the set temperature.

Your boiler also has an interesting hysteresis function, which, as I understand it, means that when you reach the set temperature, from now on the boiler heats only at the minimum power, but it can overheat the water by the set hysteresis value, i.e. you set the boiler to 50 and having a hysteresis of 5 degrees, the boiler can heat water to 55 degrees, constantly heating on minimum power before turning off the burner at 55 degrees.

There is no typical hysteresis value in your boiler, but there is a temperature interval parameter ranging from -2 to -15 degrees, the factory default value is -6.

I'm not 100% sure, but I assume it works like this.

If you set the interval to -6, then after setting 50 degrees, the boiler heats up to a maximum of 56, but after turning off the burner, it will turn on heating after the temperature drops to 44 degrees. In addition, there is also the parameter of the temporary blocking of the burner, so the actual time of firing the burner may be different.

Now, an example and my guesses on how your boiler works.

Suppose you set your boiler to 50 degrees and you have a factory temperature interval of -6.

When you turn on the burner, you have 30 degrees in the installation.

The boiler starts with the starting power X.

It goes into the 12.5kW indirect power mode and heats all the time until it reaches about 50 degrees, then it modulates and goes down to a minimum power of 4.8kW and heats with this power of 4.8kW until it reaches 56 degrees, unless earlier the room regulator turns off the heating request.

If you now set the same temperature interval -6 on the boiler to 44 degrees, assuming that the boiler turns on at e.g. 30 degrees in the system.

it heats with a power of 12.5kW until it reaches about 44 degrees, then it heats with a minimum power of 4.8kW until it reaches 50 degrees. It will be turned on again after the water has dropped to at least 38 degrees.

I hope that you would like to read my elaboration carefully and that it will be useful for you and it will not be wasted.

I do not give a 100% guarantee, because I do not have this boiler to test, but for a while as an amateur I had to deal with the Junkers MIDI, Compact and Bosch 2200 and I came to such conclusions during a one-time, short contact with these boilers.

I am more of a practitioner, so I like to have the equipment in my hand to be able to play with it, but I will not buy and exchange boilers for tests, so my practical knowledge is limited, but I already have a small vision as to how I would like my boiler to work in my apartment.

Added after 8 [minutes]: the above applies to work with the ON-OFF regulator, because CW400 controls the boiler operation and instead of working with an intermediate power of 12.5kW until reachingof the example 44 degrees, the boiler can be turned on with a lower power, as diodak_13 wrote earlier, but if the boiler is too oversized, then in my opinion such intelligent control loses its importance.