I have a question for my colleagues who are knowledgeable on the subject.

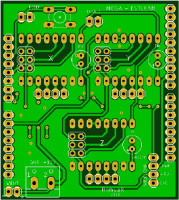

Is it possible to "force" Shield CNC v.3 to work with Arduino Mega 2560 with GRBL loaded?

It is true that sellers claim that MEGA 2560 is compatible with Shield CNC just like UNO, but this is probably not true. Arduno UNO with GRBL works with Shield CNC without any problems, but MEGA does not! From what I managed to find out, the appropriate pinouts in both boards are not in the same places (pins).

Is it possible to "force" Shield CNC v.3 to work with Arduino Mega 2560 with GRBL loaded?

It is true that sellers claim that MEGA 2560 is compatible with Shield CNC just like UNO, but this is probably not true. Arduno UNO with GRBL works with Shield CNC without any problems, but MEGA does not! From what I managed to find out, the appropriate pinouts in both boards are not in the same places (pins).