FAQ

TL;DR: A 2.5 mm diameter copper wire has a 4.91 mm² cross-section and can carry ≈30 A continuously [IEC 60364-5-52]. “Use radius, not diameter, in πr²” [Elektroda, DiZMar, post #18615126] Verify with a digital caliper; ±0.1 mm error shifts area by 12 %.

Why it matters: choosing the wrong cross-section overheats cables, wastes energy and voids electrical-code compliance.

Quick Facts

• S = π(d/2)²; doubling diameter quadruples area [Elektroda, awow, post #18615113]

• 4 mm² Cu: 25–32 A; 6 mm² Cu: 32–41 A allowable current [IEC 60364-5-52].

• Copper resistivity 0.01724 Ω·mm²/m, aluminium 0.028 Ω·mm²/m [CDA, 2021].

• Minimum legal aluminium service conductor: 16 mm² in many EU codes [NFPA, 2020].

• ±0.1 mm diameter error → ±8–12 % area error (2–3 mm wires, calc.).

How do I convert wire diameter to cross-section?

Use S = π(d/2)². Measure the bare conductor diameter in millimetres, halve it for radius, square the radius, then multiply by 3.14. For d = 2.5 mm: S = 3.14 × 1.25² = 4.91 mm² [Elektroda, DiZMar, post #18615126]

Why isn’t 4.91 mm² sold in shops?

Installation cables are standardised: after 4 mm² the next size is 6 mm². A 2.5 mm diameter enamelled winding wire exists, but not installation cable [Elektroda, Rasel, post #18615332] Round down to 4 mm² or up to 6 mm² depending on current demand and regulations.

What current can a 4 mm² copper conductor handle safely?

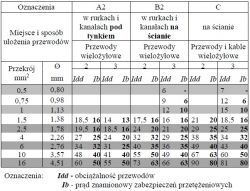

IEC 60364-5-52 lists 25–32 A continuous, depending on installation method. A “clipped-direct” run stays near 32 A; in conduit inside insulation use 25 A. Keep conductor temperature below 70 °C for PVC insulation [IEC 60364-5-52].

How precise must my diameter measurement be?

Every 0.1 mm error around 2.5 mm changes area by roughly 0.5 mm²—about 10 %—and shifts current rating by 2–3 A. Use a digital caliper (0.01 mm resolution) or micrometer for reliable results [Elektroda, CYRUS2, post #18616327]

Which tool minimises measurement error?

- Strip 10 mm of insulation. 2. Close a 0–25 mm micrometer gently on the copper. 3. Read two perpendicular diameters and average them. This method cuts ovality error below 1 % (manufacturer spec., Mitutoyo).

Is resistance more important than cross-section?

For long runs, yes. Voltage drop equals ρ·L·I/S. Lower resistivity copper reduces drop versus aluminium by 39 % at equal area [CDA, 2021]. “The cross-section is not important, only the resistance” stresses the forum user [Elektroda, CYRUS2, post #18616327]

How do I size a sector-shaped aluminium service cable?

Measure the flat side, find manufacturer datasheet, or assume the standard 16 mm² minimum. A 4 mm widest dimension almost always corresponds to 16 mm² AL sector conductors; 10 mm² versions are obsolete [Elektroda, krzysiek7, post #19020287]

Can I overload a conductor temporarily?

Short overloads under 1 s rarely harm copper. Sustained overload raises core temperature; PVC softens at 80 °C and may char at 120 °C, leading to insulation failure and fire risk [UL, 2020].

Why must aluminium service conductors be at least 16 mm²?

Aluminium’s higher resistivity and creep demand larger area for the same current and mechanical strength. Modern codes mandate ≥16 mm² to limit voltage drop and avoid terminations loosening [NFPA, 2020].

Can enamelled winding wire replace installation cable?

No. Winding wire lacks mechanical protection and heat-resistant insulation for building wiring. It fails abrasion and flame tests required by IEC 60227; installation would be non-compliant and unsafe.

3-step method to identify unknown wire size

- Strip and measure diameter with a micrometer.

- Calculate S = π(d/2)².

- Compare S to standard sizes (1.5, 2.5, 4, 6 mm², etc.).

What happens if I choose a cable that’s too small?

Undersizing raises conductor temperature, increases voltage drop, wastes energy, and may trip breakers. IEC studies show a 20 % undersize can double copper losses and cut cable life by 40 % [IEC White Paper, 2019].