Internet-of-things applications are built on intelligent, networked electronic devices that are most likely battery-powered and transmit pre-processed data to a cloud-based infrastructure. An IoT device uses a variety of embedded systems, including processors, communication ICs and sensors, to gather data, process it and then send it back to a hub or another network node. This can range from a straightforward temperature sensor that relays the current room temperature to a central monitoring location to a machine health monitor that keeps track of the long-term performance data of very expensive production machinery.

IoT applications

The use cases for IoT devices are essentially limitless. Applications that use smart transmitters receive information about their surroundings before making decisions like managing the temperature, sounding alerts or automating processes. Moreover, portable devices like gas meters and air-quality measurement systems send precise measurements to a control center over the cloud. GPS tracking technology is another use case. Via the use of intelligent ear tags, they enable the tracking of both cattle and cargo containers. They make up a minuscule portion of cloud-connected gadgets. Applications for infrastructure sensing and wearable health care are some more applications. Industrial IoT applications, a component of the Fourth Industrial Revolution, are a key growth sector.

Design challenges

Running power to most IoT nodes is not an option because they are typically placed after the fact or in challenging locations. This indicates that batteries and/or energy gathering are their sole power source.

Large facilities can be highly expensive to move power around. Take the case of a remote IoT node in a factory as an illustration. The only remaining alternatives for powering these remote nodes are battery power or energy harvesting, because installing a new power cable would be expensive and time-consuming.

The device’s total cost of ownership is impacted by the necessity to adhere to a strict power budget to maximize the battery’s lifespan. The requirement to replace the battery once its life has passed is another drawback of battery use. Included in this is the price of the battery itself, as well as the likely high expense of hiring workers to replace and possibly get rid of the old battery.

Also, overdesigning the battery increases its size and expense. Thus, it is crucial to optimize the power budget and reduce energy consumption wherever feasible to install the smallest battery while still meeting your design requirements.

There are three main types of power sources for IoT applications:

• Devices that rely on non-rechargeable battery power (primary battery)

• Devices that require rechargeable batteries

• Devices that utilize energy harvesting to provide system power

Primary battery

In these applications, the device periodically wakes up before returning to a power-efficient deep-sleep state. Its power source’s high energy density and straightforward construction are key benefits. Batteries are not ideal for situations where power consumption is slightly higher, though, as they have a limited lifespan

Making the best use of the energy offered by different power sources is the main difficulty from a design standpoint. Making a power budget plan is crucial to maximizing the battery’s lifespan, with 10 years being a typical lifetime goal.

A low-power DC-to-DC converter, such as the Analog Devices LTC3336, with an extremely low quiescent current (a few nanoamperes) is a typical device ideal for non-rechargeable battery-powered IoT devices.

The LTC3337, a nano-power primary battery state-of-health monitor and coulomb counter, is the companion device of the LTC3336. Just strap the IPK pins in accordance with the peak current necessary in the 5-mA to 100-mA range to utilize this device in a new design. Perform a few computations using your chosen battery, then fill in the recommended output cap using the chosen peak current from the datasheet.

Rechargeable battery

Rechargeable batteries are a good solution for higher-power or higher-drain IoT applications in which frequent replacement of the primary battery is not an option. Due to the initial cost of the batteries and the charging electronics, rechargeable battery applications are more expensive. Still, in higher-drain applications in which the batteries are regularly discharged and recharged, the expense is justifiable and quickly recouped. Another option, but mainly for short-term backup storage, is a capacitor or supercapacitor, depending on the power requirements.

The charger must be shrewd enough to enter pre-charge mode when the battery is severely drained to gradually raise the voltage to a safe level before switching to constant-current mode. When the battery voltage reaches the programmed float voltage, the charger switches to constant-current mode and injects the programmed current into the battery. The charge current zeroes out at the float voltage, which is then sustained for a while depending on the termination method.

The LTC4162 is an example of a buck battery charger. It can supply a charge current of up to 3.2 A and is appropriate for various applications, including portable equipment and those requiring bigger or multicell batteries. Moreover, solar energy can be used to charge the device.

Energy-harvesting applications

Energy harvesting enables the conversion of numerous energy sources, including solar, piezoelectric, vibrational, thermoelectric and RF energy, into electricity.

The initial cost is higher than the other power sources mentioned previously, as an energy-conversion IC, a harvesting device and related enabling components are required. The size of the total solution is yet another drawback, especially when compared with a power source like a coin-cell battery.

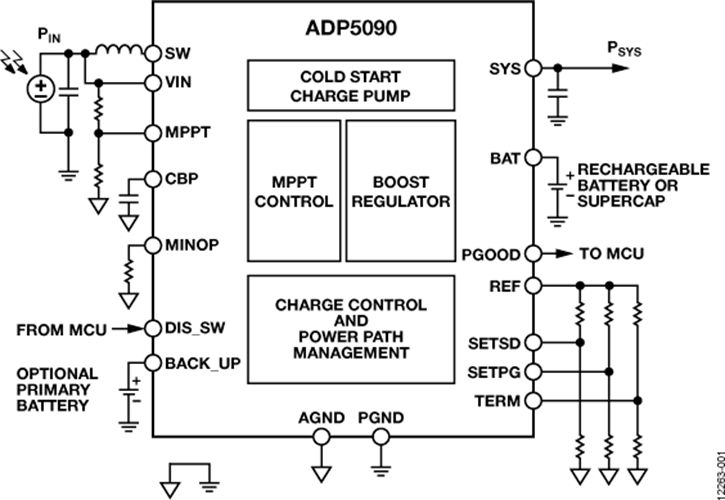

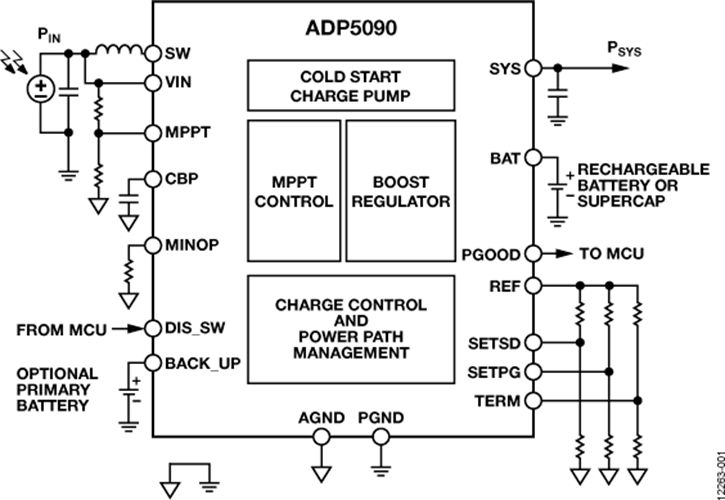

Low energy levels can be difficult to handle from an efficiency standpoint. This is because many power sources need to be rectified. After all, they are AC. This is accomplished through diodes. The designer must handle the energy loss brought on by these qualities. As you increase the input voltage, this effect is minimized, but that’s not always possible. The devices that pop up in most energy-harvesting discussions are from the ADP509x family of products and the LTC3108, which can accommodate a wide range of energy-harvesting sources with multiple power paths and programmable charge management options that offer the highest design flexibility.

Read the original article here.

After reading this article:

• What are your feelings about IoT battery-powered devices?

• Will energy harvesting compete with rechargeable batteries in terms of performance?

• What are the bottlenecks of power management design in IoT devices?

IoT applications

The use cases for IoT devices are essentially limitless. Applications that use smart transmitters receive information about their surroundings before making decisions like managing the temperature, sounding alerts or automating processes. Moreover, portable devices like gas meters and air-quality measurement systems send precise measurements to a control center over the cloud. GPS tracking technology is another use case. Via the use of intelligent ear tags, they enable the tracking of both cattle and cargo containers. They make up a minuscule portion of cloud-connected gadgets. Applications for infrastructure sensing and wearable health care are some more applications. Industrial IoT applications, a component of the Fourth Industrial Revolution, are a key growth sector.

Design challenges

Running power to most IoT nodes is not an option because they are typically placed after the fact or in challenging locations. This indicates that batteries and/or energy gathering are their sole power source.

Large facilities can be highly expensive to move power around. Take the case of a remote IoT node in a factory as an illustration. The only remaining alternatives for powering these remote nodes are battery power or energy harvesting, because installing a new power cable would be expensive and time-consuming.

The device’s total cost of ownership is impacted by the necessity to adhere to a strict power budget to maximize the battery’s lifespan. The requirement to replace the battery once its life has passed is another drawback of battery use. Included in this is the price of the battery itself, as well as the likely high expense of hiring workers to replace and possibly get rid of the old battery.

Also, overdesigning the battery increases its size and expense. Thus, it is crucial to optimize the power budget and reduce energy consumption wherever feasible to install the smallest battery while still meeting your design requirements.

There are three main types of power sources for IoT applications:

• Devices that rely on non-rechargeable battery power (primary battery)

• Devices that require rechargeable batteries

• Devices that utilize energy harvesting to provide system power

Primary battery

In these applications, the device periodically wakes up before returning to a power-efficient deep-sleep state. Its power source’s high energy density and straightforward construction are key benefits. Batteries are not ideal for situations where power consumption is slightly higher, though, as they have a limited lifespan

Making the best use of the energy offered by different power sources is the main difficulty from a design standpoint. Making a power budget plan is crucial to maximizing the battery’s lifespan, with 10 years being a typical lifetime goal.

A low-power DC-to-DC converter, such as the Analog Devices LTC3336, with an extremely low quiescent current (a few nanoamperes) is a typical device ideal for non-rechargeable battery-powered IoT devices.

The LTC3337, a nano-power primary battery state-of-health monitor and coulomb counter, is the companion device of the LTC3336. Just strap the IPK pins in accordance with the peak current necessary in the 5-mA to 100-mA range to utilize this device in a new design. Perform a few computations using your chosen battery, then fill in the recommended output cap using the chosen peak current from the datasheet.

Rechargeable battery

Rechargeable batteries are a good solution for higher-power or higher-drain IoT applications in which frequent replacement of the primary battery is not an option. Due to the initial cost of the batteries and the charging electronics, rechargeable battery applications are more expensive. Still, in higher-drain applications in which the batteries are regularly discharged and recharged, the expense is justifiable and quickly recouped. Another option, but mainly for short-term backup storage, is a capacitor or supercapacitor, depending on the power requirements.

The charger must be shrewd enough to enter pre-charge mode when the battery is severely drained to gradually raise the voltage to a safe level before switching to constant-current mode. When the battery voltage reaches the programmed float voltage, the charger switches to constant-current mode and injects the programmed current into the battery. The charge current zeroes out at the float voltage, which is then sustained for a while depending on the termination method.

The LTC4162 is an example of a buck battery charger. It can supply a charge current of up to 3.2 A and is appropriate for various applications, including portable equipment and those requiring bigger or multicell batteries. Moreover, solar energy can be used to charge the device.

Energy-harvesting applications

Energy harvesting enables the conversion of numerous energy sources, including solar, piezoelectric, vibrational, thermoelectric and RF energy, into electricity.

The initial cost is higher than the other power sources mentioned previously, as an energy-conversion IC, a harvesting device and related enabling components are required. The size of the total solution is yet another drawback, especially when compared with a power source like a coin-cell battery.

Low energy levels can be difficult to handle from an efficiency standpoint. This is because many power sources need to be rectified. After all, they are AC. This is accomplished through diodes. The designer must handle the energy loss brought on by these qualities. As you increase the input voltage, this effect is minimized, but that’s not always possible. The devices that pop up in most energy-harvesting discussions are from the ADP509x family of products and the LTC3108, which can accommodate a wide range of energy-harvesting sources with multiple power paths and programmable charge management options that offer the highest design flexibility.

Read the original article here.

After reading this article:

• What are your feelings about IoT battery-powered devices?

• Will energy harvesting compete with rechargeable batteries in terms of performance?

• What are the bottlenecks of power management design in IoT devices?

Cool? Ranking DIY