The battery management system (BMS) is an essential component of any electric vehicle, tasked with monitoring the battery’s state of charge (SOC) and state of health (SOH).

To operate reliably and over a long period, lithium-ion batteries must be used with particular care: They must never be completely discharged and the SOC must be constantly monitored. The capacity of the individual cells decreases over time in a different way from cell to cell, and therefore, each cell must be managed individually to prevent it from being completely discharged.

To supply sufficient energy to operate a vehicle, dozens or hundreds of cells connected in series and capable of generating a very high overall voltage, up to 800 V and above, are used. The battery electronics must be able to operate with such high voltages and cancel the effects of the common-mode voltage while simultaneously controlling each cell of these strings. The electronics must also be able to communicate information related to each cell to a central monitoring system.

The BMS must guarantee the maximum possible energy, duration, safety and reliability while reducing costs, dimensions and weight.

Wired BMS

A battery management IC measures each cell in a typical EV battery pack. The pack ECU is then informed of data from the battery management IC through wire.

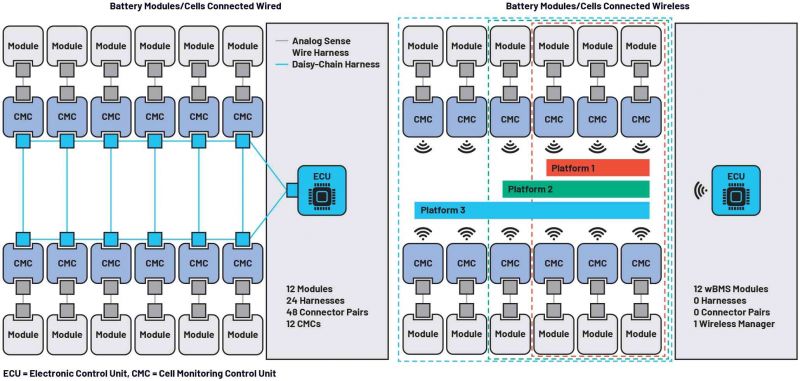

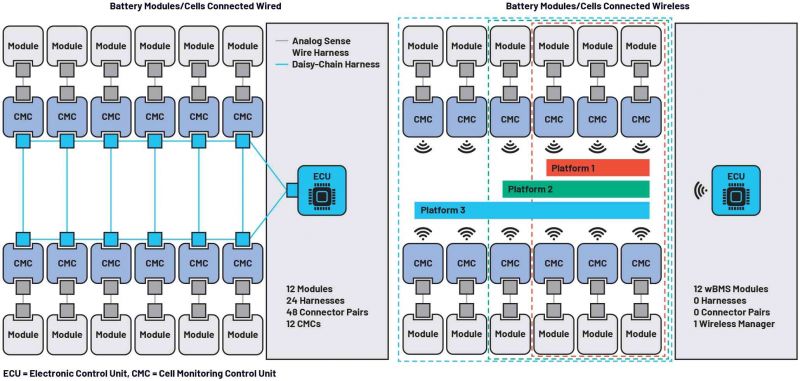

The essential battery operation parameters (voltage, charge/discharge current and temperature) must be tracked and logged separately for each module to maximize battery capacity, longevity and performance. Traditionally, the connections between each module and the ECU processor have been made with wires, as shown on the left of Figure 1.

Figure 1: A typical multicomponent wired BMS network (left) and the simpler

arrangement made possible by wireless BMS technology (right)

However, wired connections have some disadvantages, as copper wiring harness adds additional weight and occupies space that, if filled by a battery cell, would provide extra energy capacity. In addition, connectors may mechanically fail, especially in situations of vibration and shock, and the wire must be secured to the battery housing structures.

This results in higher cost, weight and development time, as well as a reduction in reliability, available space and driving range. Given those requirements, there are compelling arguments for automakers to integrate a reliable wireless technology into new EV battery system platforms.

Wireless BMS

The newly released wireless BMS (wBMS) technology gives automakers a competitive advantage for the entirety of a battery’s life, from initial battery module assembly through use in an EV to disposal and, if necessary, into the battery’s second life.

Car manufacturers can easily incorporate the wBMS into the design of a battery pack because it is a comprehensive solution. Each battery module has a wireless cell-monitoring controller (wCMC) unit, and there is also a wireless manager unit for managing the communications network that wirelessly connects the various battery modules to the ECU. Each wCMC unit also has a BMS, which measures numerous battery characteristics with extreme accuracy. This allows the applications processing unit to assess the batteries’ SOC and SOH.

Although the wiring harness design and assembly issue has been completely resolved by wBMS technology, there are still other aspects of the battery life cycle where value can be increased:

• Battery assembly: The power connections required by a battery module can be easily made in a highly automized process, eliminating manual labor for assembly and testing. Modules can also be tested and matched before installing inside the battery.

• Servicing: Due to its wireless interface, the status of the battery pack can be explored and analyzed by diagnostics equipment in an authorized service station without touching the pack, improving safety and reducing time of fault analysis.

• Second life: A market for used EV batteries that have been recovered from abandoned vehicles and put to use in things like renewable-energy–storage systems and electric power tools is growing along with the number of vehicles. As wBMS enables a simpler integration of the modules for second-life applications, it also generates a new source of value for EV producers, who are responsible for the recycling or disposal of the batteries in scrapped EVs.

• Disposal: Battery packs need to be disposed of according to recognized and controlled procedures because they include recyclable metal and possibly dangerous elements. With a wireless approach, the removal of the battery modules is simpler and faster than with a wired battery because of the straightforward connections and lack of a communications wiring harness.

• Data management: Critical battery data from each intelligent module can be read out quickly and easily thanks to wBMS technology. This implies that each battery’s state can be assessed separately. For example, this data may reveal details about the SOC and SOH of a module. This enables the best use of the module in its second-life application and the availability of a thorough set of specifications for each module now for sale, when combined with information from the module’s initial production. The module’s resale value is raised by the ready accessibility of this data.

When it comes to wireless solutions, the topic of security plays a fundamental role. In fact, data transmission must be protected by encryption, thus preventing hackers or ill-intentioned people from intercepting sensitive information, or even injecting data that could compromise the correct functioning of the BMS or battery.

For these reasons, wBMS systems are designed in accordance with the ISO 26262 functional safety standard. Furthermore, a good immunity to interference and noise that can be generated in the automotive typical environment must be guaranteed.

Read the original article here.

After reading this article, what are your feelings about wBMS technology?

Will wBMS become the standard in next-generation EVs?

In addition to reducing polluting emissions, what other technical solutions capable of revolutionizing the classic concept of the car will EVs introduce?

To operate reliably and over a long period, lithium-ion batteries must be used with particular care: They must never be completely discharged and the SOC must be constantly monitored. The capacity of the individual cells decreases over time in a different way from cell to cell, and therefore, each cell must be managed individually to prevent it from being completely discharged.

To supply sufficient energy to operate a vehicle, dozens or hundreds of cells connected in series and capable of generating a very high overall voltage, up to 800 V and above, are used. The battery electronics must be able to operate with such high voltages and cancel the effects of the common-mode voltage while simultaneously controlling each cell of these strings. The electronics must also be able to communicate information related to each cell to a central monitoring system.

The BMS must guarantee the maximum possible energy, duration, safety and reliability while reducing costs, dimensions and weight.

Wired BMS

A battery management IC measures each cell in a typical EV battery pack. The pack ECU is then informed of data from the battery management IC through wire.

The essential battery operation parameters (voltage, charge/discharge current and temperature) must be tracked and logged separately for each module to maximize battery capacity, longevity and performance. Traditionally, the connections between each module and the ECU processor have been made with wires, as shown on the left of Figure 1.

Figure 1: A typical multicomponent wired BMS network (left) and the simpler

arrangement made possible by wireless BMS technology (right)

However, wired connections have some disadvantages, as copper wiring harness adds additional weight and occupies space that, if filled by a battery cell, would provide extra energy capacity. In addition, connectors may mechanically fail, especially in situations of vibration and shock, and the wire must be secured to the battery housing structures.

This results in higher cost, weight and development time, as well as a reduction in reliability, available space and driving range. Given those requirements, there are compelling arguments for automakers to integrate a reliable wireless technology into new EV battery system platforms.

Wireless BMS

The newly released wireless BMS (wBMS) technology gives automakers a competitive advantage for the entirety of a battery’s life, from initial battery module assembly through use in an EV to disposal and, if necessary, into the battery’s second life.

Car manufacturers can easily incorporate the wBMS into the design of a battery pack because it is a comprehensive solution. Each battery module has a wireless cell-monitoring controller (wCMC) unit, and there is also a wireless manager unit for managing the communications network that wirelessly connects the various battery modules to the ECU. Each wCMC unit also has a BMS, which measures numerous battery characteristics with extreme accuracy. This allows the applications processing unit to assess the batteries’ SOC and SOH.

Although the wiring harness design and assembly issue has been completely resolved by wBMS technology, there are still other aspects of the battery life cycle where value can be increased:

• Battery assembly: The power connections required by a battery module can be easily made in a highly automized process, eliminating manual labor for assembly and testing. Modules can also be tested and matched before installing inside the battery.

• Servicing: Due to its wireless interface, the status of the battery pack can be explored and analyzed by diagnostics equipment in an authorized service station without touching the pack, improving safety and reducing time of fault analysis.

• Second life: A market for used EV batteries that have been recovered from abandoned vehicles and put to use in things like renewable-energy–storage systems and electric power tools is growing along with the number of vehicles. As wBMS enables a simpler integration of the modules for second-life applications, it also generates a new source of value for EV producers, who are responsible for the recycling or disposal of the batteries in scrapped EVs.

• Disposal: Battery packs need to be disposed of according to recognized and controlled procedures because they include recyclable metal and possibly dangerous elements. With a wireless approach, the removal of the battery modules is simpler and faster than with a wired battery because of the straightforward connections and lack of a communications wiring harness.

• Data management: Critical battery data from each intelligent module can be read out quickly and easily thanks to wBMS technology. This implies that each battery’s state can be assessed separately. For example, this data may reveal details about the SOC and SOH of a module. This enables the best use of the module in its second-life application and the availability of a thorough set of specifications for each module now for sale, when combined with information from the module’s initial production. The module’s resale value is raised by the ready accessibility of this data.

When it comes to wireless solutions, the topic of security plays a fundamental role. In fact, data transmission must be protected by encryption, thus preventing hackers or ill-intentioned people from intercepting sensitive information, or even injecting data that could compromise the correct functioning of the BMS or battery.

For these reasons, wBMS systems are designed in accordance with the ISO 26262 functional safety standard. Furthermore, a good immunity to interference and noise that can be generated in the automotive typical environment must be guaranteed.

Read the original article here.

After reading this article, what are your feelings about wBMS technology?

Will wBMS become the standard in next-generation EVs?

In addition to reducing polluting emissions, what other technical solutions capable of revolutionizing the classic concept of the car will EVs introduce?

Cool? Ranking DIY