Hallo members,

I would like to manage the Domestic Hot Water Production (DHW) of a Vaillant combined boiler ecoCOMPACT VSC IT 246/2-C 170 by an external relé.

The system is equipped with the additional unit calorMATIC VRC 430 and the external temperature sensor. In any case, I'm not currently interested in using the calorMATIC device because I have a random use of DHW, so the weekly program function does not fit my needs as well as the possibility to maintain hot water at a set temperature value continuously.

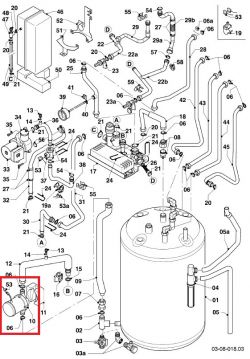

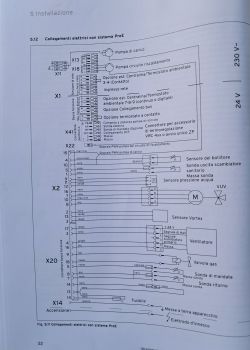

The Central Heating system (CH) is managed by relé using the RT 230 V - AC connector (violet and orange conductors in the attached picture) and I would be great to do the same for DHW, setting a fixed value of the hot water by knob and managing the ON/OFF DHW production without the use of eBUS.

I have also attached some pictures for a more clear idea of the current configuration and reference wiring diagram.

Thanks a lot for any advice.

I would like to manage the Domestic Hot Water Production (DHW) of a Vaillant combined boiler ecoCOMPACT VSC IT 246/2-C 170 by an external relé.

The system is equipped with the additional unit calorMATIC VRC 430 and the external temperature sensor. In any case, I'm not currently interested in using the calorMATIC device because I have a random use of DHW, so the weekly program function does not fit my needs as well as the possibility to maintain hot water at a set temperature value continuously.

The Central Heating system (CH) is managed by relé using the RT 230 V - AC connector (violet and orange conductors in the attached picture) and I would be great to do the same for DHW, setting a fixed value of the hot water by knob and managing the ON/OFF DHW production without the use of eBUS.

I have also attached some pictures for a more clear idea of the current configuration and reference wiring diagram.

Thanks a lot for any advice.