Hi!

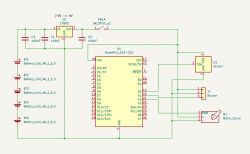

I am putting together a project that needs to work in the field for as long as possible. The batteries need to be easily accessible, so I have decided on AA batteries. I have ensured that all components can be powered by 5 volts. I would very much appreciate your review of the design in the appendix and any suggestions you may have. I am particularly concerned with the power supply, I have never done anything like this:

.

.

100 nF ceramic capacitors, because that's what I have. The servo is a Feetech F5109M standard. The stabiliser is a 5 volt L7805ABV. If I understand correctly, I could add another battery there to increase the length of the project. Warm regards!

I am putting together a project that needs to work in the field for as long as possible. The batteries need to be easily accessible, so I have decided on AA batteries. I have ensured that all components can be powered by 5 volts. I would very much appreciate your review of the design in the appendix and any suggestions you may have. I am particularly concerned with the power supply, I have never done anything like this:

.

.100 nF ceramic capacitors, because that's what I have. The servo is a Feetech F5109M standard. The stabiliser is a 5 volt L7805ABV. If I understand correctly, I could add another battery there to increase the length of the project. Warm regards!