Hello

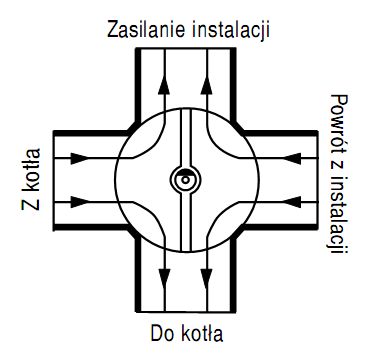

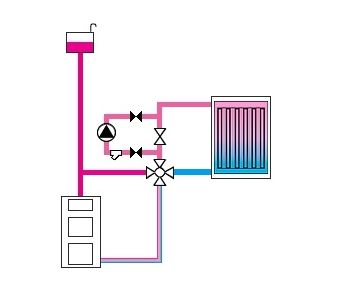

Since Saturday, I have had the pleasure of using a new CO installation and I have a problem with setting the four-headed valve and I would like to ask for such an explanation of this problem (manually controlled valve)

Thanks in advance for your help

Regards

Damian

Since Saturday, I have had the pleasure of using a new CO installation and I have a problem with setting the four-headed valve and I would like to ask for such an explanation of this problem (manually controlled valve)

Thanks in advance for your help

Regards

Damian