I confirm. The description of the photos from the first post is correct. As predecessors wrote: needles are to stick to the line, and the wire is braided with three forks.

In the case of wire, The forks are made in such a way (looking from the bottom of the plug from the pin side) so that when placed one next to the other, they do not cause a short circuit (two forks go one way, and one middle forks in the other - you can see how they are bent just before tightening, after carefully examining the plug) on the side).

It still exists

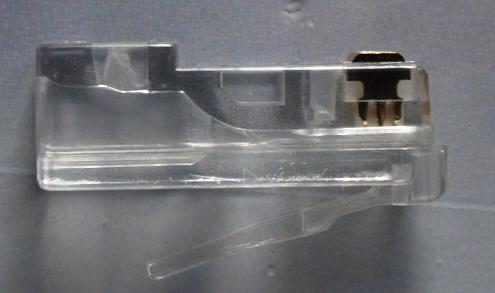

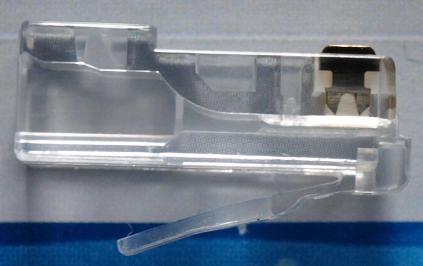

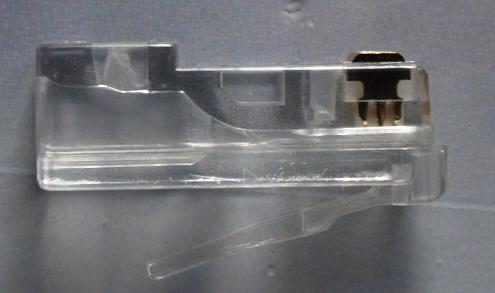

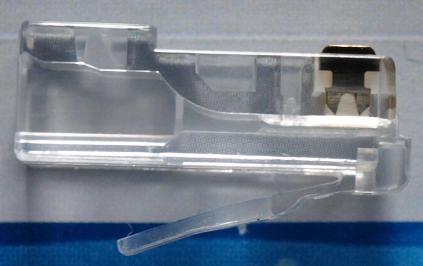

the third type of plug, the so-called universal (both for wire and rope)

They are very similar to the lanyard ones. They have "double forks", but after careful inspection you can see that one of the forks is cut one way and the other is cut the other way.

The idea is that in the case of a line, they should normally stick into the center of the core (and this is what usually happens), while in the case of a wire, they should diverge: one to the left, the other to the right

(precisely due to the fact that they have alternately cut tips) In practice, it comes out differently, depending on the quality of the crimper.

To sum up: (from my several years of practice) Any type of tip will be tightened on the "poverty" rope, it will be fully clamped (in the sense that the pins will be deeply seated) and it should work (good contact and no short circuits).

However, it is best of course to use line ends.

With the wire, the matter becomes more complicated. As a general rule of thumb, crimping the ends onto a wire should be avoided. We put the wire only from the socket to the panel in the closet. However, in practice we know that sometimes it is necessary to do otherwise

Therefore, someone came up with tips for wire.

Now I will describe my experiences with crimping different ends FOR WIRE:

The ends are intended for the line (personally, I never did it, because it shouldn't be, but I saw the previous admin at work).

There are two possible effects: If the press tool has the correct (perpendicular) application of force, the needle is FORCED into the wire. It will not pierce this wire (no chance) - the effect is that the tip works, but the pins are not fully tightened. The effect of connecting such a plug to devices is such that the pins in the sockets start to bend too much. Later, after connecting a correctly clamped plug, it is enough to slightly withdraw it (RJ'ka, as we know, has some play in the socket, despite the latched dowel) and it stops connecting. In addition, plugs tightened in such a way you can immediately recognize the fact that, looking from the side of the dzyndzl, the wires are even pressed against the wall (knocked out of insulation).

The second possible effect is that we have a poor quality press tool that applies some force to the side. The effect is that the needles slide off the wires and stick between the veins. In this case it is a lottery: it will either work or it will work and sometimes .. stop .. why ??

Once I fought with several computers on which several times a day was "Network cable disconnected" and then the message disappeared after a while. No movement of the plug on the card or switch had any effect. The cable was checked with a simple tester (4 diodes indicating the efficiency of individual pairs in turn). The cable is wire, of course. As it turned out ? Short circuit between adjacent pins in the plug. These neighbors were one of the transmission cores (10/100 standard) and the remaining unused wire (connected to ground in 10/100 devices). It caused such degradation of the signal that .. the 3coma power cable managed, however, with a few exceptions per day.

Now for the best for last. I have tried to crimp these ends several times. This time I used dedicated wire tips (those with 3 forks). The crimper was weak (for PLN 60). Wasted a few plugins. There was a short circuit each time. Although the plugs were wired, after crimping it it was obvious that the pins were not driven in as they should.

In the case of all types of plugs, when crimped, when viewed from the side of the diaphragm, the tips of the needles sticking out of the core layer should be clearly visible. As for crimping universal terminals on a wire, I will only say that with a good crimping tool everything should be OK. However, I have the impression that the dedicated ones are better, but I noticed another problem. For a long time (2-3 years) sold wire ends do not tighten as nicely as they used to be. This is not only my opinion, but also a few experienced installers who I know.

Therefore, nowadays the safer choice are universal tips + good (read above PLN 100) crimping tool. If the crimper is cheap and of poor quality, it is only suitable for crimping on a rope.