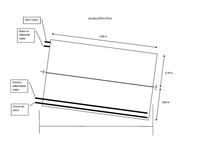

Due to the costs of factory-made devices for heat accumulation, and the problem with bringing in a ready-made device, I am thinking of having such a buffer welded out of 6mm sheet metal. I am limited by the width of the cellar door of 80 cm, so I decided to make two elements with dimensions of 2 x 1 x 0.78 m collar, turn in the basement and put on some stand. I don't need any coils at the moment, everything will go together. The boiler is wood-fired 30KW, open system. The house is tiny so there is a large excess of boiler power in relation to the demand. I only burn wood.

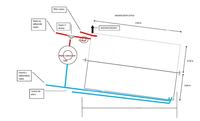

I am wondering about the problem of the proximity of the inlet pipe from the furnace to the outlet to the heat receivers, i.e. so that the water does not go from the furnace and is immediately sucked into the heat receivers. Water will be pumped from the boiler by a pump, similarly as from the buffer to the heat receivers. How to solve it? As for the returns, I will lead the pipes through the entire buffer so that the stove sucks in water from the lowest point, and it will be similar back from the heat receivers. (access to the buffer will be only on the left side of the image)

I will leave a few stubs at different heights so that in the future you can add some more devices, and of course some sockets for thermometers, etc.

I also wonder if it makes sense to paint the buffer from the inside, if so, with what. I heard an opinion that after some time the paint will be garbage in the installation and the walls will still be covered with limescale.

Another problem is the connection of both elements, how to seal it so that it does not leak.

Thermal insulation is planned with mineral wool, but I do not know what is best to put on top of the insulation.

I saw that some buffers use funnels inside, which is supposed to be related to better water circulation. I plan to give some reinforcements so that the buffer does not deform.

I will be grateful for any suggestions and comments regarding my project.

I am wondering about the problem of the proximity of the inlet pipe from the furnace to the outlet to the heat receivers, i.e. so that the water does not go from the furnace and is immediately sucked into the heat receivers. Water will be pumped from the boiler by a pump, similarly as from the buffer to the heat receivers. How to solve it? As for the returns, I will lead the pipes through the entire buffer so that the stove sucks in water from the lowest point, and it will be similar back from the heat receivers. (access to the buffer will be only on the left side of the image)

I will leave a few stubs at different heights so that in the future you can add some more devices, and of course some sockets for thermometers, etc.

I also wonder if it makes sense to paint the buffer from the inside, if so, with what. I heard an opinion that after some time the paint will be garbage in the installation and the walls will still be covered with limescale.

Another problem is the connection of both elements, how to seal it so that it does not leak.

Thermal insulation is planned with mineral wool, but I do not know what is best to put on top of the insulation.

I saw that some buffers use funnels inside, which is supposed to be related to better water circulation. I plan to give some reinforcements so that the buffer does not deform.

I will be grateful for any suggestions and comments regarding my project.