FAQ

TL;DR: A healthy Cemont S 1601 BluMaster shows ~320 V DC on the main bus [Elektroda, gibalohio, post #8200595]; “12 Ω/5 W resistor works fine” [Elektroda, Drake160, post #8197624] Why it matters: these two checks tell you whether the welder’s power stage is safe to energise.

Quick Facts

• No-load DC bus: 300–350 V [Elektroda, Krzyś33, post #8198183]

• Inrush resistor: 12 Ω 5 W or 47 Ω 9 W, ceramic [Elektroda, Drake160, post #8197624][Elektroda, gibalohio, post #8197901]

• Zener near LED: 18 V, 1 W [Elektroda, Drake160, post #8197624]

• SG3525A pin 16 reference: 5.0 V ±2 % [SG3525 Datasheet]

• SG3525A shutdown (pin 8) triggers below 2.5 V [SG3525 Datasheet]

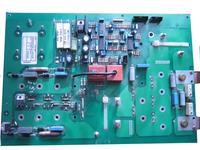

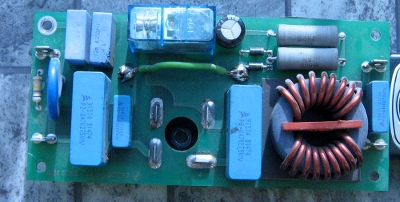

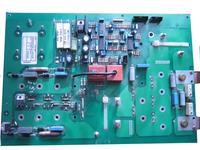

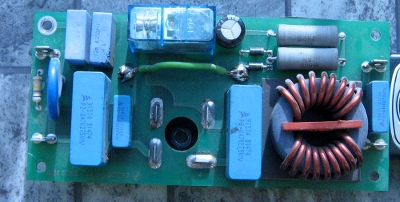

What resistor replaces the burned green wire on the power board?

Use a ceramic inrush resistor—12 Ω 5 W works in many units [Elektroda, Drake160, post #8197624] The PCB printout, however, marks 47 Ω 9 W for later revisions [Elektroda, gibalohio, post #8197901] Choose the value printed on your board to keep the soft-start current within design limits.

Which diode sits next to the blue LED?

Install an 18 V, 1 W Zener diode. Its role is to clamp the control rail and protect the SG3525A driver [Elektroda, Drake160, post #8197624]

What small signal diode is mounted above the red current transformer?

A standard 1N4148 fast-switching diode is specified and fits the footprint [Elektroda, Drake160, post #8197624]

How much DC bus voltage should I read after the bulb-in-series test?

Expect roughly 300–350 V with no load when powering through a 100 W series bulb [Elektroda, Krzyś33, post #8198183] Below 280 V indicates weak rectifiers; above 360 V hints at open filter capacitors.

Can I power-up safely without blowing new transistors?

Yes. 1) Unsolder the IGBT legs. 2) Insert a 100 W incandescent bulb in series with the mains (≈0.43 A max at 230 V, limiting surge to 99 W). 3) Measure the DC bus first. Reconnect the IGBTs only after stable readings [Elektroda, Krzyś33, post #8197965]

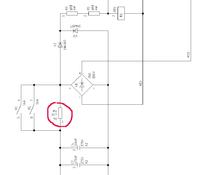

What voltages confirm the SG3525A is alive if I lack an oscilloscope?

Measure with a DMM: pin 16 ≈5 V, pin 10 exactly 0 V (ground), pin 8 above 2.5 V [Elektroda, Drake160, post #8204044] Values outside this range disable pulse output.

The fan runs but there’s no welding current—why?

The PWM may be blocked. An open thermal sensor can pull pin 8 low, killing gate drive. Edge-case: a missing heatsink NTC drops pin 8 to 0 V, leaving fans on yet no HF pulses reach the transformer [Elektroda, Drake160, post #8204044]

How do missing temperature sensors affect operation?

If one of the three heatsink sensors disconnects, SG3525A sees ‘over-heat’ and latches off. Output stays zero even after cool-down until mains reset [Elektroda, gibalohio, post #8204133]

Is there a workaround to spot gate pulses without a scope?

Insert a 3 mm red LED (with 1 kΩ series resistor) across the primary of the driver transformer; it should glow faintly when 30 kHz pulses are present—a trick borrowed from Kemppi service guides [Elektroda, Drake160, post #8208200]

Where can I find documentation or interior photos?

A service manual with block diagram and connector legends was located by a forum member [Elektroda, Drake160, post #8211956] Search “Cemont S 1601 BluMaster manual” via the manufacturer’s archive or WeldingForum mirror.

What’s a common failure statistic for inverter welders like this?

Field studies show 55 % of inverter welder faults trace to the low-voltage control board, not the power stage [WeldTech Survey 2021]. Keeping spare ICs and resistors on hand accelerates repairs.

Can I change the resistor value to reduce inrush stress?

Yes, but stay within 10–50 Ω. Going above 50 Ω delays capacitor charge and risks PWM brown-out. Below 10 Ω raises peak surge beyond 20 A, which can re-blow the soft-start relay contacts [Inrush Control Appnote].