Present your solutions for mounting cameras on polystyrene (facade).

I often have this problem with my clients and I don't know how to deal with it.

I often have this problem with my clients and I don't know how to deal with it.

Czy wolisz polską wersję strony elektroda?

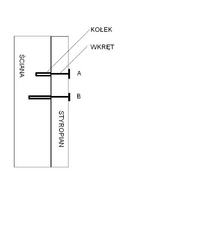

Nie, dziękuję Przekieruj mnie tamrokycky wrote:1) You cut out a place for a wooden block in the foam, which you will cover with a handle, fasten it with long pins and screw the handle from the camera to the block.

LoLek85 wrote:Buddy Jacek, read my post again and think about what you wrote. If you don't understand, I can even draw it for you ...

Jacek28 wrote:kkknc wrote:I extend the screws by the length of the polystyrene.

For what purpose, then, such a long peg? Probably half the shorter length would keep the camera even on such a long screw.

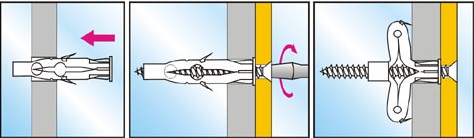

kkknc wrote:To understand this, you need to know the structure of an expansion plug and the principle of its operation. Just don't answer that you know or you wouldn't ask that question above.

eworks wrote:Get interested in Fischer and their solutions for various substrates, they are expensive, but they are not for mass production like putting plastic trays ;-)

Greetings.

kkknc wrote:I see that, however, you do not know the construction of the peg and how it works.

sharp wrote:Only this "short pin with a long screw" will push the handle into the polystyrene as the screw is screwed in - there is no "limiter", which is the collar of the long pin.

Especially if the spacing of the holes in the holder is quite small.

Porotherm and various other hollow bricks are also annoying.

extremeee wrote:SM pins and low pressure foam ?? I admire the invention, but I do not push such combinations to my clients. What about attempts to break / devastate the camera? What is the durability of this ??

extremeee wrote:By the way, if you grind the heads of the studs, how then do you disassemble the camera in the event of a failure?