What current?

Czy wolisz polską wersję strony elektroda?

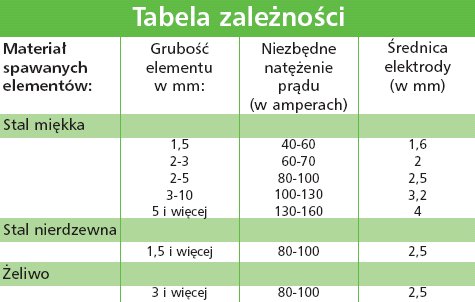

Nie, dziękuję Przekieruj mnie tamDam_MS wrote:Hello, I am a beginner in electrode welding. I have a question, what current should be set using the electrode Fi 3.25 by 4 mm ?

I heard that the amount of current we operate depends on the diameter of the electrode - is the thesis with the multiplication of the diameter by 30 authentic? If not, how to convert it.