I warmly welcome,

For some time I have been trying to make a table for my equipment - a future-proof design - it is supposed to be for many years.

The problem in my case is probably the project, which, unfortunately, is not a problem-free one, although I was stubbornly stubborn.

Plan:

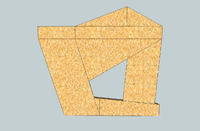

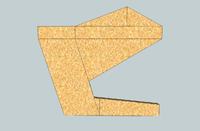

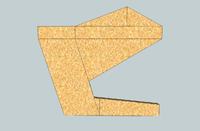

side shape:

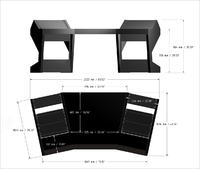

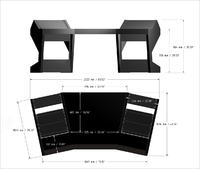

Module:

top - 2 x 10u, 19 '' rack

bottom - 2 x 12u, 19 '' rack

Initially, I planned to make the entire structure of 40mm MDF - I am quite green in terms of carpentry, so I consulted this with a carpenter, who said MDF is not enough due to the shape of the sides, which will have to bear quite a lot of weight in the form of studio equipment in the future.

However, I would like to ask you - does it actually have no right to exist? In this arrangement, I thought about making the side modules of plywood, and only the top top made of MDF - but in the case of plywood, the costs increase significantly (about PLN 1200 for the material only to the sides, which, unfortunately, I cannot afford)

2nd question - where can rack strips be purchased at reasonable prices? Or is it better to use blacksmith services?

In fact, any advice or idea for this project is worth its weight in gold for me.

Thank you and best regards.

For some time I have been trying to make a table for my equipment - a future-proof design - it is supposed to be for many years.

The problem in my case is probably the project, which, unfortunately, is not a problem-free one, although I was stubbornly stubborn.

Plan:

side shape:

Module:

top - 2 x 10u, 19 '' rack

bottom - 2 x 12u, 19 '' rack

Initially, I planned to make the entire structure of 40mm MDF - I am quite green in terms of carpentry, so I consulted this with a carpenter, who said MDF is not enough due to the shape of the sides, which will have to bear quite a lot of weight in the form of studio equipment in the future.

However, I would like to ask you - does it actually have no right to exist? In this arrangement, I thought about making the side modules of plywood, and only the top top made of MDF - but in the case of plywood, the costs increase significantly (about PLN 1200 for the material only to the sides, which, unfortunately, I cannot afford)

2nd question - where can rack strips be purchased at reasonable prices? Or is it better to use blacksmith services?

In fact, any advice or idea for this project is worth its weight in gold for me.

Thank you and best regards.