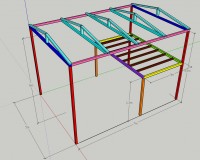

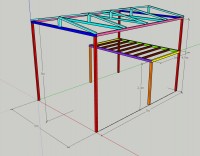

Hi, I am planning to build a 5x7m garage with something like a mezzanine, with the rest I am enclosing a sketch:

And I wonder if I should go for a sandwich panel instead of classic blocks, bricks, etc. I want, among other things, that there are no hornets or other locusts anywhere, and it seems to me that in the case of sandwich panels, joints, etc., are so tight that it should be successful, and with boards or blocks it can be different. Well, the time to erect something from the boards is a few days, not counting the foundation, and bricklaying, insulation, plastering of classic buildings six months in my edition

The problem, however, is that all ready-made projects on the net are made in 90% on porotherm - you know, the architect does not have to make any effort because a skyscraper can be placed on such a 25 cm wall. I even asked in 3 places how much to do the project, but they wrote to me that they didn't, so I assume that if I went to a specialist with it, he would cut me like a lock of Steven Segal's hair.

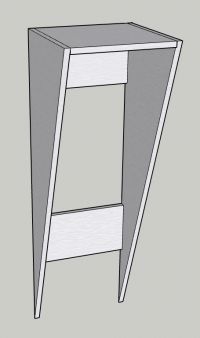

So the question is, is anyone able to tell me what profiles to make such a garage from?

The weight of a square meter of the sandwich panel is about 10-15 kg and on this mezzanine in gusts I would like to load, say, 2 tons. And on the purple beam, I would like to have an I-section for extracting the engine, e.g.

Anyone can help or should I fall on a tree?

And I wonder if I should go for a sandwich panel instead of classic blocks, bricks, etc. I want, among other things, that there are no hornets or other locusts anywhere, and it seems to me that in the case of sandwich panels, joints, etc., are so tight that it should be successful, and with boards or blocks it can be different. Well, the time to erect something from the boards is a few days, not counting the foundation, and bricklaying, insulation, plastering of classic buildings six months in my edition

The problem, however, is that all ready-made projects on the net are made in 90% on porotherm - you know, the architect does not have to make any effort because a skyscraper can be placed on such a 25 cm wall. I even asked in 3 places how much to do the project, but they wrote to me that they didn't, so I assume that if I went to a specialist with it, he would cut me like a lock of Steven Segal's hair.

So the question is, is anyone able to tell me what profiles to make such a garage from?

The weight of a square meter of the sandwich panel is about 10-15 kg and on this mezzanine in gusts I would like to load, say, 2 tons. And on the purple beam, I would like to have an I-section for extracting the engine, e.g.

Anyone can help or should I fall on a tree?