Hello

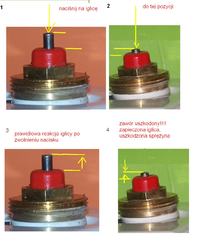

I have a problem, or rather a query, I have valves on the return shown in the photo:

To the point, I marked the thread on which the cover cap comes in green, the key can be put on red, and the hexagon socket in blue and turned to the right or left. My question is, if I put the key on what I have marked in red, can I completely unscrew the inside of this valve and plug it with a screw-on plug (marked in green)?

I have the impression that the flow is poor, the radiators' pits are cold, the Allen adjustment probably does not work, I don't really have the patience for it anymore ... I just want to improve the flow. I messed up a bit with what I wrote, but I hope it is understandable.

Thanks in advance for any answers. Sorry if I posted my question in the wrong section. greetings

I have a problem, or rather a query, I have valves on the return shown in the photo:

To the point, I marked the thread on which the cover cap comes in green, the key can be put on red, and the hexagon socket in blue and turned to the right or left. My question is, if I put the key on what I have marked in red, can I completely unscrew the inside of this valve and plug it with a screw-on plug (marked in green)?

I have the impression that the flow is poor, the radiators' pits are cold, the Allen adjustment probably does not work, I don't really have the patience for it anymore ... I just want to improve the flow. I messed up a bit with what I wrote, but I hope it is understandable.

Thanks in advance for any answers. Sorry if I posted my question in the wrong section. greetings