Hello, I am asking for help with the Spark 130 inverter welding machine. The welder does not turn on - none of the diodes on the housing is on (there are two from the power supply and the other from overheating).

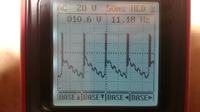

After dismantling I found a damaged rectifier diode on the secondary bridge with the designation STTH2003CG, it is SMD diode, 300V, 10A, 35ns. The diode had a short circuit, I could not solder it and it remained with the legs cut off, after connecting to the power supply, the output waveform is like in the picture - only slight sparking is visible during the welding test. The rest of the bridges are efficient.

What should I pay attention to and what else to measure? The tile was soldered with a series of goldpins, unfortunately, when I unraveled the path was not durable - now I did it on wires - it is possible to disassemble.

After dismantling I found a damaged rectifier diode on the secondary bridge with the designation STTH2003CG, it is SMD diode, 300V, 10A, 35ns. The diode had a short circuit, I could not solder it and it remained with the legs cut off, after connecting to the power supply, the output waveform is like in the picture - only slight sparking is visible during the welding test. The rest of the bridges are efficient.

What should I pay attention to and what else to measure? The tile was soldered with a series of goldpins, unfortunately, when I unraveled the path was not durable - now I did it on wires - it is possible to disassemble.