I would do this:

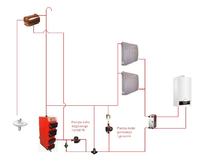

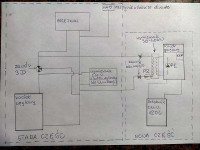

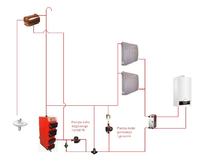

The idea of operation is simple.

1. Coal boiler.

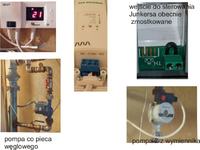

The boiler pump turns on only when the stove reaches 45'C. The 3D thermostatic valve separates the boiler and radiator circuits. It opens only when the water in the short circuit of the boiler reaches the valve opening temperature, e.g. 45'C.

The advantage of this solution are two functions. One is to protect the boiler return temperature and the other is to cut off the boiler circuit after the boiler has cooled down.

2. Gas boiler.

Starting the gas boiler also turns on the heating circuit pump. Of course, I assume that the gas boiler is equipped with a pump and a safety group ...

Starting the gas boiler can be controlled by plugging into the room thermostat output and setting the boiler accordingly. The room thermostat is an ON OFF contact and there is no problem to use a relay, e.g. from the boiler pump.

The gas boiler will not ignite earlier until the coal boiler cools down and the 3D valve cuts off the circuit.

In the event of a failure, the pumps stop. Gas boiler too. If such a situation occurs, the differential valve at the boiler will open the gravitational circuit to the radiators. If the installation is done correctly (pipe diameters, radiators, slopes, radiator valves with increased flow), the system will work. It doesn't have to be the entire installation. It is enough to prepare one riser for gravity, where there are the most radiators.

So, if a failure occurs while burning in a coal-fired boiler and it is solidly fired up, there will be no problem with boiling the boiler.

The circuit of the heat exchanger and gas boiler, if the boiler is not equipped with a non-return valve, it should be used. We will eliminate the risk of heating the boiler by gravity.