I read a little and

the split exchanger is based on R410a - this refrigerant has a high pressure of 20 bar.

automotive exchangers are usually R134 and there is less pressure so they may not withstand.

You can also buy plate heat exchangers or counter-flow heat exchangers - pipe in a pipe. The price of such an exchanger is about PLN 1500, so a lot.

The idea of immersing the evaporator splits in the boiler is the safest in terms of factor compatibility, pressure compliance. Risks are what you write that the exchanger will corrode and the gas pressure will go to heating (here it should be secured by a safety group). Well, how long will it last, because if, for example, 2 years, the skin is not worth a layette.

In addition, there is the problem of sealing the copper pipes in the boiler and welding it. The water circuit should also be pressurized to about 2atm (floor heating), drill a hole in the boiler, insert a pipe, seal it with some putty? it may not work for a long time.

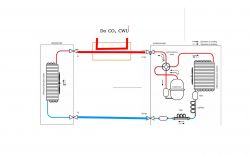

http://www.chelchowski.pl/pliki/oferta/ODZYSK%20STOJI.bmp I already have a KLIMA, but in any case, you still have to spend 1500 or 2000 on the exchanger (the so-called hydrobox). Well, it is not known whether it will be a success or a failure

So in the end it seems to me that despite the seemingly simple idea, it is still not very feasible.