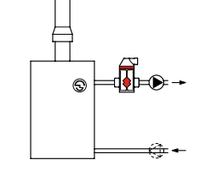

I have a problem with the electronic central heating pump. Previously, the pump was installed on the return, but this system did not work well, so this year it was installed on the power supply. My problem is that at temperatures above 75 degrees on the stove, the pump airs out and slows down to the lowest power, and thus the temperature on the stove increases because only 2 radiators heat up. There is no vent at the pump, and it does not force it to work faster when there is air in it, so the only way is to loosen the screw connection behind it or try to lower the temperature on the stove. When looking for a solution, I installed a separator, but it only helped with the occasional squeaking of the pump. I have no idea what to do, so as not to wonder every time I am not at home or the pump sometimes did not want to slow down, so I am asking you for help, which may be the reason.