Hello,

I had a problem with the vacuum pump recently, because after starting the car after a long stop, it took a while (one-two minutes) to brake.

I replaced the vacuum pump (due to the current weather and lack of time during the day) I drove the car to the mechanic.

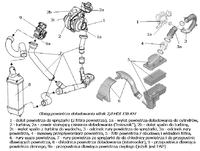

The pump has been exchanged for efficient use. The problem with brake support disappeared, but already on the way from the mechanic I noticed the problem (smoking exhaust from the exhaust stench like from an old tractor). After 10 km, it stopped. After returning, a mistake appeared. After connecting to the computer it turned out that there is a flow meter error. The specialist mechanic has twisted but to put it neatly there was no motivation. It turned out that the plug is not plugged into the flow meter and the air hose from the filter is not twisted with bands at all.

There is one more problem, I hear now when accelerating (on a loaded engine) hissing. Rather, it is related to the work of turbo (I look so much like hearing) but never before there were such sounds. Hissing is sometimes loud, sometimes quiet, sometimes disappears completely.

I am not able to listen to it under the hood, because I will not be able to go there as soon as I come in ...

And at the stop, hissing is not audible (the engine is not loaded).

This has also occurred hissing several times when the engine is braked at a certain higher rpm range.

In addition, the engine pulls, there are no errors, the intake hose hardens as it cools.

But if it lost its flexibility. He likes to tame at lower revolutions.

I had a problem with the vacuum pump recently, because after starting the car after a long stop, it took a while (one-two minutes) to brake.

I replaced the vacuum pump (due to the current weather and lack of time during the day) I drove the car to the mechanic.

The pump has been exchanged for efficient use. The problem with brake support disappeared, but already on the way from the mechanic I noticed the problem (smoking exhaust from the exhaust stench like from an old tractor). After 10 km, it stopped. After returning, a mistake appeared. After connecting to the computer it turned out that there is a flow meter error. The specialist mechanic has twisted but to put it neatly there was no motivation. It turned out that the plug is not plugged into the flow meter and the air hose from the filter is not twisted with bands at all.

There is one more problem, I hear now when accelerating (on a loaded engine) hissing. Rather, it is related to the work of turbo (I look so much like hearing) but never before there were such sounds. Hissing is sometimes loud, sometimes quiet, sometimes disappears completely.

I am not able to listen to it under the hood, because I will not be able to go there as soon as I come in ...

And at the stop, hissing is not audible (the engine is not loaded).

This has also occurred hissing several times when the engine is braked at a certain higher rpm range.

In addition, the engine pulls, there are no errors, the intake hose hardens as it cools.

But if it lost its flexibility. He likes to tame at lower revolutions.