blade9999 wrote: However, I do not understand how data from the report that is generated for a given second would help in diagnosing the fault. In which specific moment should I generate a report or take a screenshot? At 2500 rpm? At 3000 rpm? Or maybe at a stop?

All reports you've put in are worthless for two reasons:

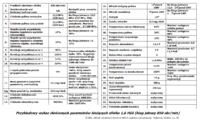

1) graphic it can not be compared whether they are good or not, because their waveforms are not parallel, literally applied to each other. You would have to print the pictures, cut them with scissors and put them together to catch the difference. This applies to the actual and set mass (lines 12 and 12a on my table), also the boost pressure (line 13) and other parameters.

So if you would already have charts to detect a disturbance in the combustion, then it would have to be at least as much as you see in my table, i.e. from 30 or more.

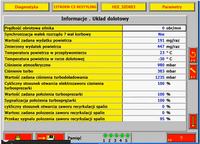

2) Tabular data they are captured only at idle (about 800 rpm). There are no parameters on

disputed turnover , which is exactly when the engine loses power. No wonder that the mechanic spreads his hands, since he has no idea that the power unit does not lose its power at idle, only while driving. So what are we going to get out of the forum if it's perfectly in the middle of the idle?

However, in order not to leave you with a feeling of disappointment, because I see that you are reading my advice with some interest, then I will lead you on a few main reasons for the loss of power. For this purpose, I paste 2 pictures, on which I marked in red the most sensitive and most often failing elements from the point of view of power and periodic jerking of the engine.

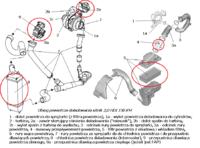

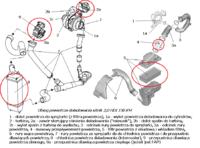

I would start from the left drawing and from the simplest things to check myself, namely

tightness and patency parts such as:

1. Air and fuel filter (invisible fuel filter, but very important). In both cases, their clogging with impurities can contribute to a power drop of more than 50%.

Due to a clogged air filter, the engine does not tug, but the fuel filter - yes, yes .

2. All air pipes (7) must be absolutely tight, undamaged, in particular the rubber section reaching the lower part

intercooler (8). It is most vulnerable to rupture due to dripping residues of hot oil as well as other contaminants. The audible sign of breaking the air pipe is the shrill whistle of the turbocharger, because the air circuit is depressurized and the sound escapes to the outside, which in normal conditions can not be heard.

The engine does not tug when damaged or clogged pipes .

3. intercooler (air-to-air cooler) (8) - the same as in the case of pipes, perforation, corrosion, and, on the other hand, clogging, e.g.

farfoclami from a broken rubber tube in question - it can cause a drastic loss of power.

When unsealed or clogged intercoolerze the engine does not tug .

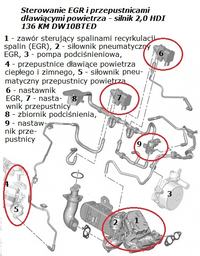

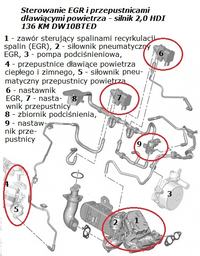

4. Throttle dampers for cold and hot air (9, 9a) + interacting with them

pneumatic cylinders (5 - second drawing) and

positioners electro-pneumatic (7, 9). Each of the above mentioned elements may contribute to the power drop by uncontrolled closing of the air supply to the intake manifold. Throttles and actuators and regulators operate pneumatically (throttles) and electro-pneumatically (regulators).

Damaged or clogged throttles, the engine does not tug .

5. Turbocharger boost pressure control (1, 1a) + interacting

pneumatic cylinder ("bellows") (2a) + electro-pneumatic

boost pressure regulator (7) +

boost pressure sensor (here invisible).

If the boost pressure control is damaged, the engine does not tug .

6. Exhaust control valve (1) + interacting

EGR pneumatic cylinder (2nd - second figure) +

exhaust gas recirculation (6) +

mass air flow meter (

mpp ) (4 - first figure).

Mechanical or electrical damage to any of the above mentioned components may contribute in addition to the power loss to the motor jerk .

A typical symptom of malfunction

EGR exhaust gas recirculation circuit there will be emission and deposition of oily soot on the air intake elements like throttling throttle below.

If a driver or mechanic sees something like that, he should be worried about the technical condition

EGR exhaust valve (1) + cooperating actuator and adjuster as well

inflating the mass of air through a flow meter .

Of course, fat deposits can also come from

pneumothorax or even from getting through

engine oil with

intercooler and damaged compressor seals, but not as much as with EGR. Unwanted or excessive amounts of EGR exhaust gases given in the wrong moment can quickly obscure the light of the air pipes by up to 50% or more, obviously leading to insufficient air. As a result, there is a dramatic drop in power and periodic jerking of the engine, despite the impeccable condition of the turbocharger and the fuel injection circuit.

7. Sensors mentioned in points 5 and 6, i.e. boost pressure sensor . mpp + air temperature sensor integrated with mpp (4) + intake manifold temperature sensor . Each of the above mentioned sensors can contribute to the power drop, a

mpp in addition to engine tugging.

Pzdr KotBury2