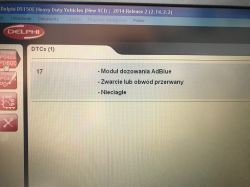

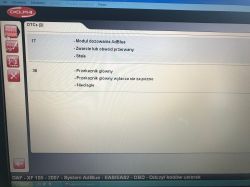

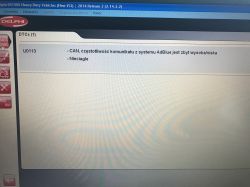

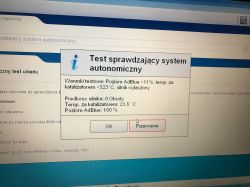

This reading from the DELPHI diagnostic device is a typical example of the uselessness of such "interfaces"

Apart from error code 5,

The second error - 61 is translated as a fault in the return path associated with defrosting AdBlue wires.

Completely brings the recipient into the field.

According to the description of the DFA error codes,

This is an error with the following title: AdBlue inlet pipe failure during detection mode

The comment on this error is as follows:

"This fault code can also occur when an EAS-2 unit

is (re-) programmed and no pressure is built up

during the first start-up of the unit.

- This fault can cause an engine derate to +/- 60% of

the maximum torque "

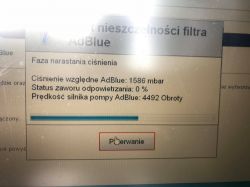

This error is generated in the initial phase of the AdBlue system, i.e. stand-up phase - preparation phase.

The system monitors the pressure build-up of AdBlue at the initial pump start.

if after starting the pump the adblue pressure does not build up (or does not exceed a certain threshold after a certain time), it assumes that the adblue supply pipe from the reservoir is blocked.

As potential reasons for this error code is given as follows:

"AdBlue inlet pipe frozen / blocked

- AdBlue inlet pipe leakage

- AdBlue filter frozen / blocked

- AdBlue filter in inlet pipe frozen /

blocked

- AdBlue pressure pipe frozen / blocked

- AdBlue pressure pipe leakage

- AdBlue pipes incorrectly connected

to tank or EAS unit

- Dosing module defective

- Ventilation valve defective (inside

EAS unit)

- AdBlue pressure sensor defective

(inside EAS unit) "

And now from the life cycle:

Most often (90% of cases),

This error is generated as the tiny filters (plastic with a tiny sieve) are screwed in to the inside of the adblue power port in the EAS team.

In order to get to it, one must disconnect the adblue feeding tube from the EAS unit (it should be quickly plugged with eg a cut finger of a rubber glove because AdBlue will be the force of gravity from it to flow out and make a mess), and with the help of a medium

flat screwdriver unscrew the filters from the inside of the power port.

The filter is inside the port at a depth of about 0.5 cm and is made of white plastic.

The sieve is often clogged with garbage from the AdBlue tank. This is the pre-filters. The main filter can not be touched because it does not physically clog.

Filterek costs one zloty and is not worth cleaning. I've always had a handful of these filters in my tool cabinets or in a van.

With the rest, unscrewing the main adblue filter will only unnecessarily inflate the adblue pump.

The remaining 10% of cases are cracked housing of the mixing module (spring wheel) due to the bursting of corrosion.

It is necessary to remove the mixing valve completely from the car (4 torx screws 30 + 10mm wrench), because the corrosion that bursts it is collected between its housing and the wall of the plate to which it is screwed.

The valve is made of aluminum alloy and the corrosion product of aluminum burst it (white powder).

However, I do not exclude the other suggestions, eg freezing AdBlue within the grid in the tank or the feed pipe itself.

this error code can also be generated if someone has used adblue-contaminated diesel oil. Sealers in the pump made of rubber swell from contact with the oil which causes the pump to physically rub off from here can not create pressure in the start phase. that is: nochala stick in the adblue tank and smell it or smell it with pus.

Let me know what you found, maybe others will benefit.