Hello.

As the topic.

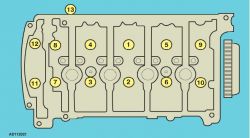

Peugeot 207 CC 1.6 16V THP car, EP6DT 2007 150HP engine.

I am interested in the tightening torques of the shaft supports and connecting rods, the flywheel, the shaft pulley, the timing diagram, the diagram of the crank-piston system, the instructions for tightening the head.

In general, all the data needed to assemble an engine from scratch.

Thank you in advance.

As the topic.

Peugeot 207 CC 1.6 16V THP car, EP6DT 2007 150HP engine.

I am interested in the tightening torques of the shaft supports and connecting rods, the flywheel, the shaft pulley, the timing diagram, the diagram of the crank-piston system, the instructions for tightening the head.

In general, all the data needed to assemble an engine from scratch.

Thank you in advance.