Since the early days of the development of electricity and electronics, there has been a need to build regulators to smoothly influence the power dissipated in a load. The first regulators, built as linear regulators, introduced huge losses on the regulating element and, while they worked relatively well for low-power devices (e.g. the speed controller of a tape-shift motor in tape recorders), this was already problematic for medium and high power. This was due to the operation of the power elements in the linear range, much less loss was provided by operation as a key (i.e. open or fully closed with the transient omitted). By controlling the ratio of open to closed time accordingly, it was possible to regulate the power of the load in a smooth manner with minimal losses in the regulator itself. Thus was born the now widely used PWM ( Pulse-Width Modulation ) or Pulse Width Modulation. PWM has found its main application in DC circuits to control the speed (power) of DC motors, heaters or the brightness of light bulbs (traditional as well as LED). The circuit itself, which generates the signal for the actuator, can be implemented in many ways, whether in discrete technology (single transistors) or based on TTL/CMOS digital circuits or even operational amplifiers or specialised PWM controller circuits. It is also easy to implement on probably virtually any microprocessor/microcontroller. One circuit often used as a PWM controller by both amateurs and professionals is the "immortal" NE555.

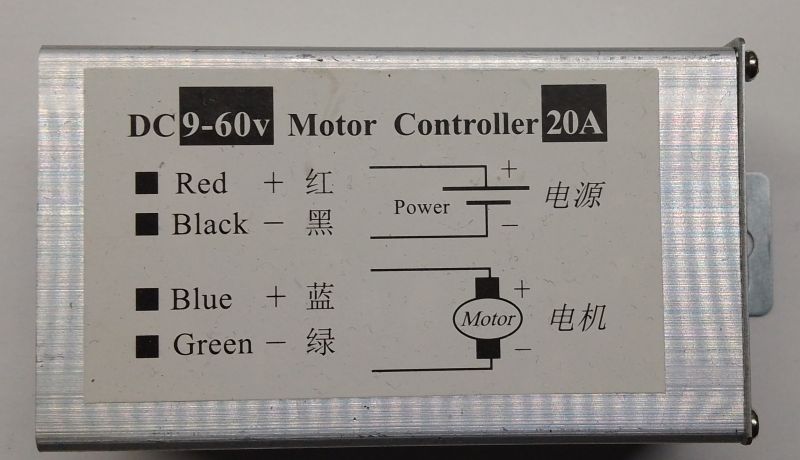

The described regulator module was given to me by a colleague, who purchased several pieces to regulate the speed of the windscreen wiper motors in his car. The module is packaged in an anti-static foil bag;

.

The described regulator module was given to me by a colleague, who purchased several pieces to regulate the speed of the windscreen wiper motors in his car. The module is packaged in an anti-static foil bag;

It gives the impression of being solidly built, the housing made of aluminium profiles with steel end caps also acts as a heat sink (although not really, but more on that later).

.

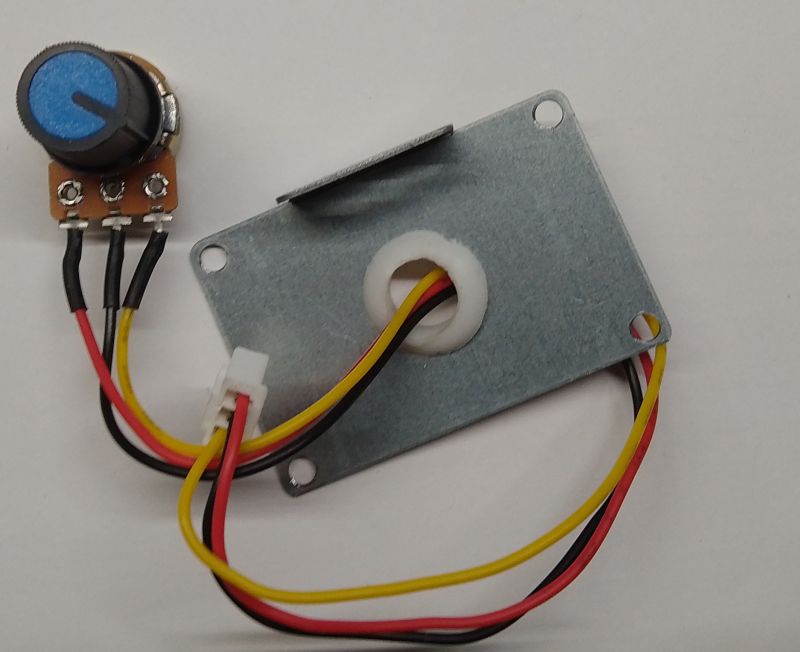

As it were, "included" we get a potentiometer for adjustment together with a knob, in the photo below I have unscrewed the cap to take a look at the interior.

.

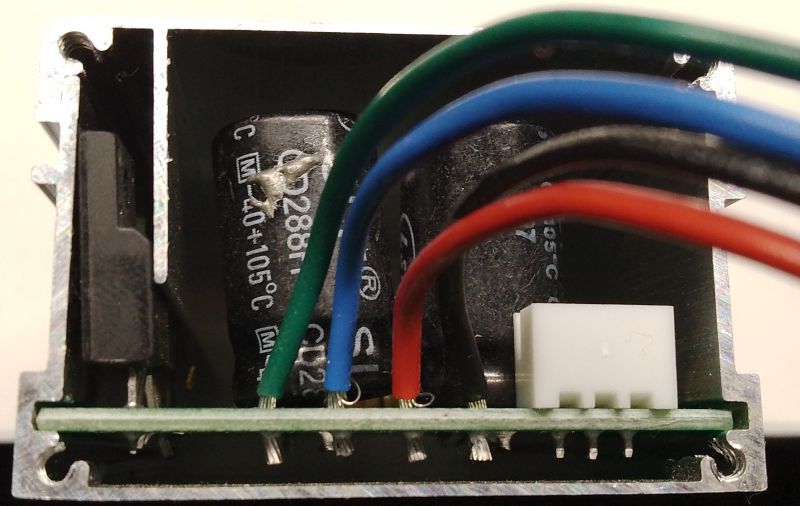

As I mentioned, the enclosure is intended to act as a heatsink and is mechanically adapted for this, however, the thermopad between the power components and the enclosure wall was missing;

.

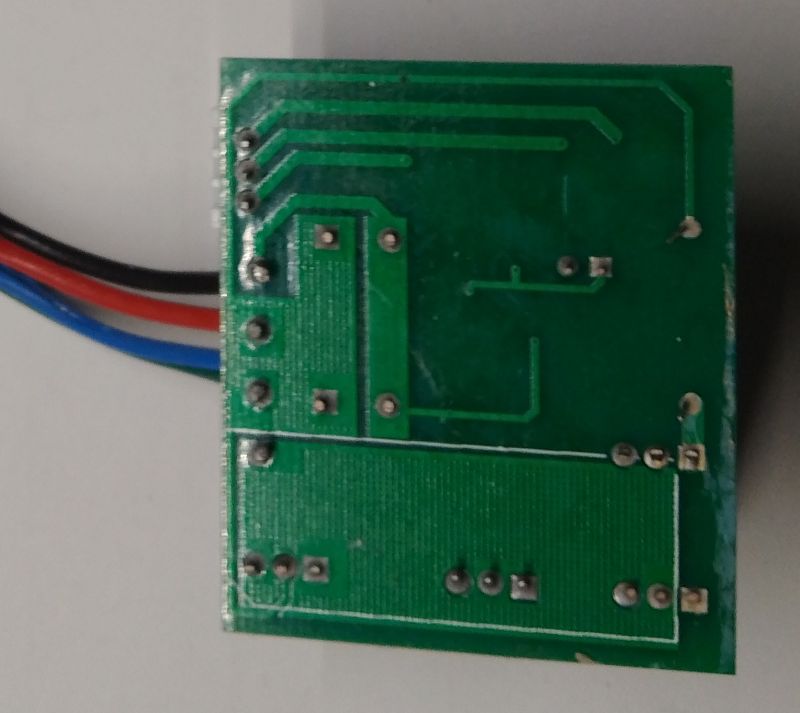

I rather don't anticipate long operation at higher currents.... The regulator board measures 47x40mm and was made as a double-sided board.

<spanclass="notranslate"> .

.

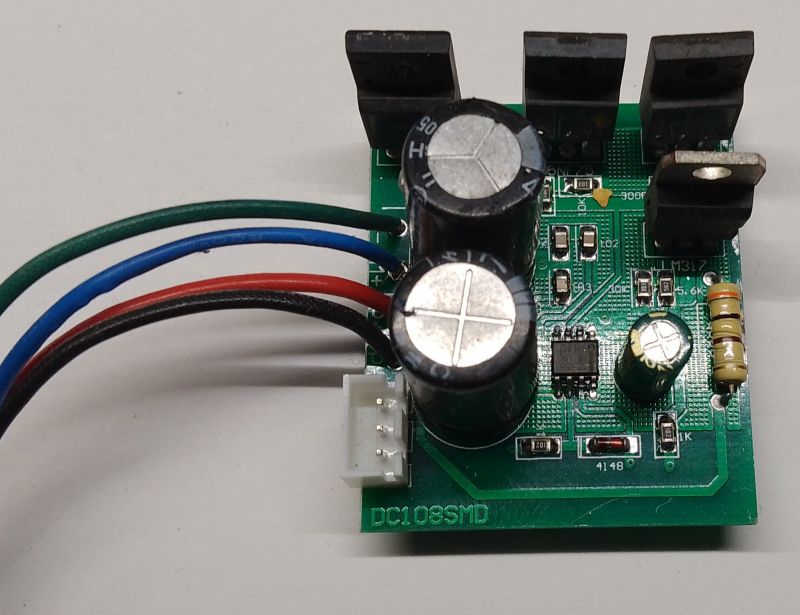

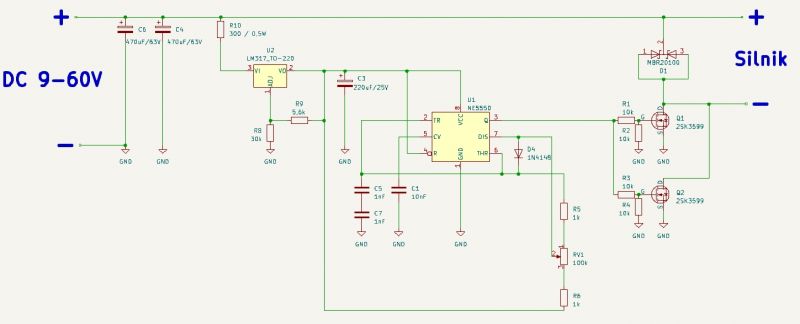

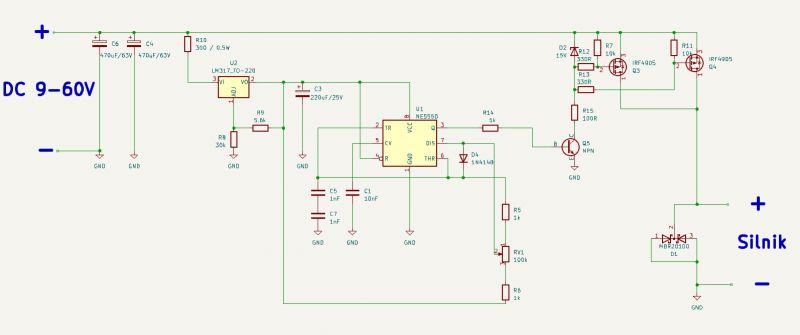

Basically, the whole regulator consists of a dozen or so components and its main component is.... NE555 precisely! I took a moment and redrew the circuit layout from the board;

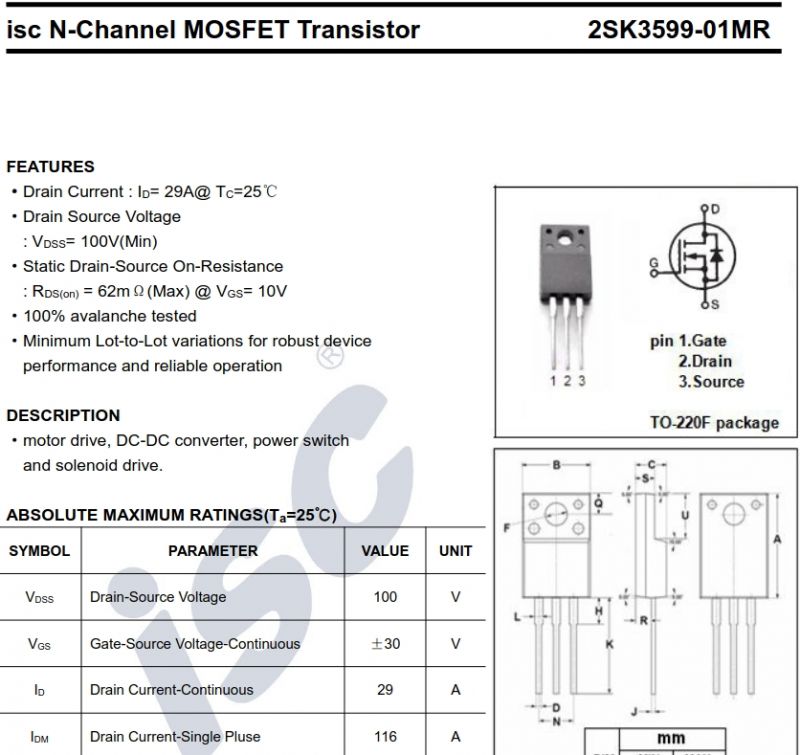

2SK3599 transistors were used as executive keys although the choice of gate resistors is questionable to me....

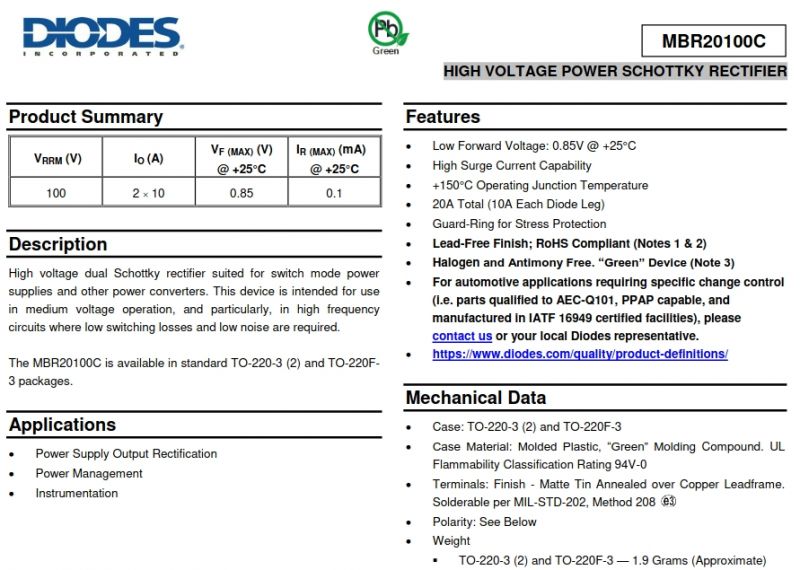

The MBR20100 duodiode is used as the pin suppressor diode;

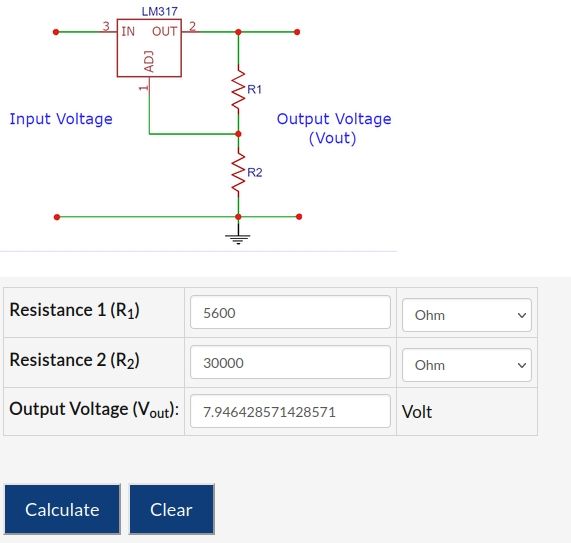

The role of the auxiliary voltage stabiliser for the NE555 is played by an LM317 with somewhat unusually selected resistors fixing the output voltage;

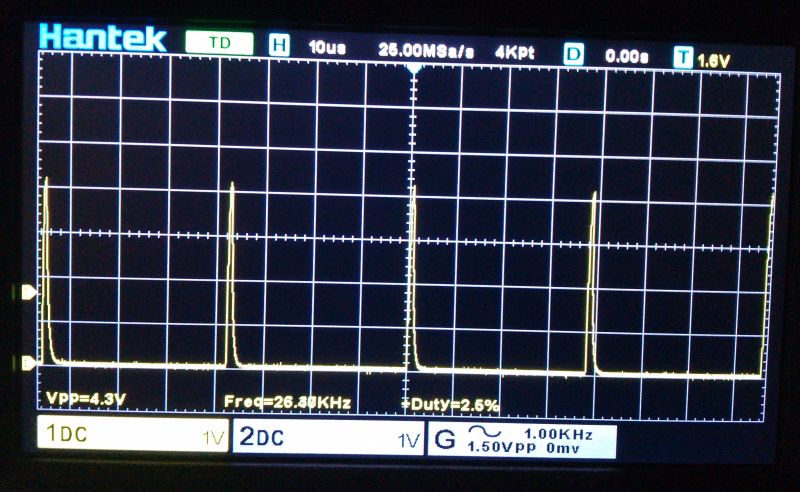

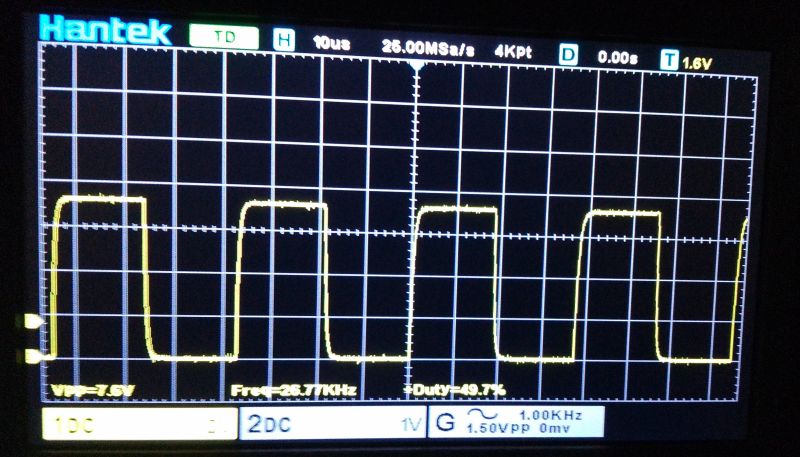

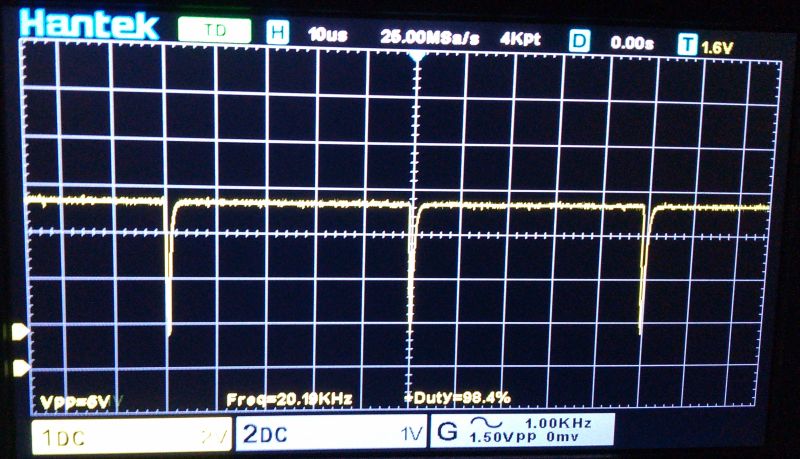

The PWM 'carrier' frequency is ~20kHz which should not produce audible effects when working with inductive loads, the fill is adjustable from about 2.5% to 98%. Below are some photos showing the minimum, average and maximum settings;

.

.

.

In truth, if I were to buy this regulator I would prefer to build it myself

Errata; .

Gate resistors are not 10k but 300Ω. Sorry for the mistake.