Hello !!!

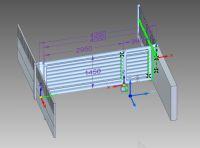

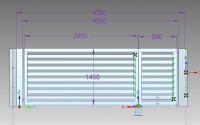

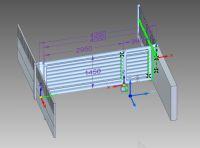

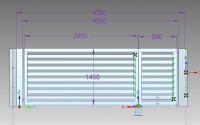

I am asking for help in choosing a double-leaf gate drive (sash width 1m and 3m) - the gate with posts 150x150mm is fitted along the entire width of the entrance - below the photo.

The wings are made of rectangular steel profiles (the weight of the wings is 30kg and 80kg, respectively).

The narrower wing is to act as a wicket, so I would like it to open fairly quickly (about 10s) - it is relatively short and light.

The second wing, due to its width and weight, cannot open in such a short time and requires the use of an appropriate actuator (for long wings).

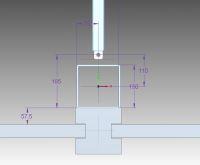

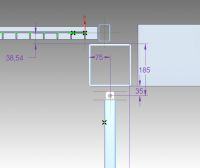

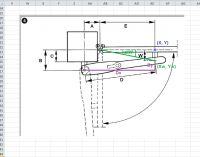

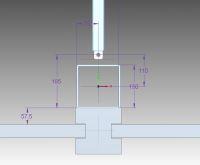

In addition, the third picture shows the dimensions of the wings' seating in relation to the post, which is to facilitate the selection of the actuator. A stop was used for both wings to relieve the cylinders in the closed position.

Drives should be powered with 24VDC due to medium intensity and the possibility of battery power in the future

I would like to fit in a budget of about 2.5 thousand.

I was thinking about using Nice Wingo3524HS, but I doubt if it can handle a wide wing.

Which producer offers a control panel where parameters (speed, force) can be programmed separately for both actuators ???

What kind of actuators should be used to achieve the above requirements (different speed and width of the wings) and cooperated with one central unit ???

I am asking for help in choosing a double-leaf gate drive (sash width 1m and 3m) - the gate with posts 150x150mm is fitted along the entire width of the entrance - below the photo.

The wings are made of rectangular steel profiles (the weight of the wings is 30kg and 80kg, respectively).

The narrower wing is to act as a wicket, so I would like it to open fairly quickly (about 10s) - it is relatively short and light.

The second wing, due to its width and weight, cannot open in such a short time and requires the use of an appropriate actuator (for long wings).

In addition, the third picture shows the dimensions of the wings' seating in relation to the post, which is to facilitate the selection of the actuator. A stop was used for both wings to relieve the cylinders in the closed position.

Drives should be powered with 24VDC due to medium intensity and the possibility of battery power in the future

I would like to fit in a budget of about 2.5 thousand.

I was thinking about using Nice Wingo3524HS, but I doubt if it can handle a wide wing.

Which producer offers a control panel where parameters (speed, force) can be programmed separately for both actuators ???

What kind of actuators should be used to achieve the above requirements (different speed and width of the wings) and cooperated with one central unit ???