Hello, I have two problems with the 2.0 TDI CR CAGB engine, so I am wrong:

5120 - Oxygen (Lambda) Sensor B1 S1

P2196 00 [237] - Signal too High (Rich)

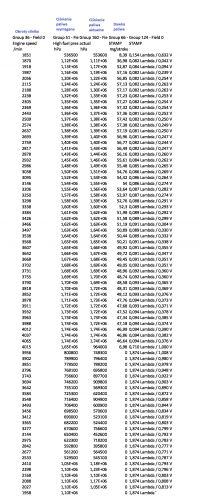

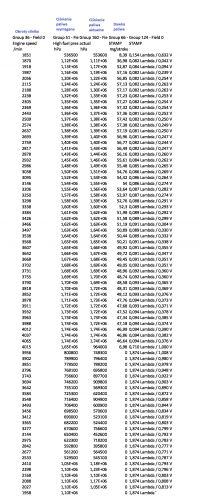

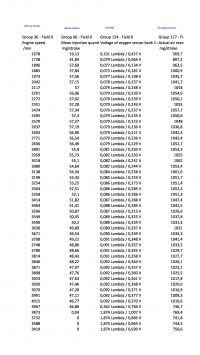

After erasing and doing about 300km the error returns, the second problem is uneven idling, shakes the engine and you can hear a two-mass wheel. I started to diagnose the fuel system, there are no filings on the CR pump in the strainer. Fuel pressure on the bar at idling very strange jumps, from 190 bars to 320, the engine shakes two-mass. The mechanic said that you need to replace the bimass because through it rages the parking dose and pressure because the computer tries to adjust the uneven rotation of the engine. It can be like that? I am afraid that I will replace the clutch and the symptoms will remain. On vcds it looks like this:

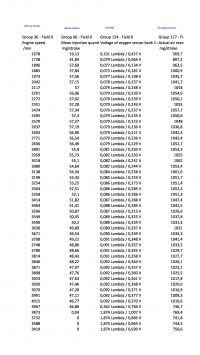

I have also made dynamic logs, fuel pressure in the entire rev range, probably good, turbo and the rest also look ok:

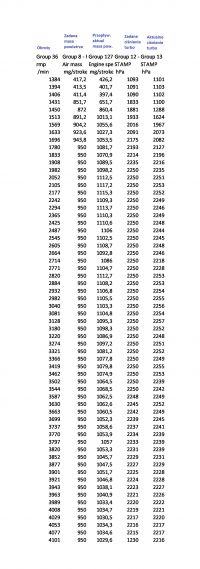

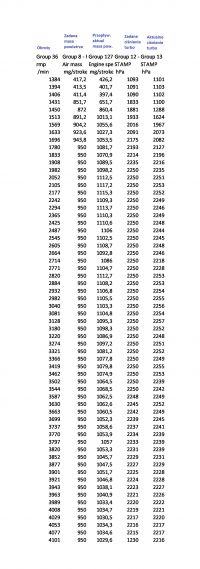

I also made an overflow test for injections:

You can see that the 2 injections are weak, maybe it crashes oxygen error with info about a rich dose. I am concerned about the idling fuel pressure, can it be the culprit two years or injection? or maybe a valve? Does the overflow test give 100% confidence that the injection is for replacement? What do you recommend to me, where to start? Injections correction are very floating, once on injection is a dose of even -2mg and in a moment can change to + 1mg, and so on almost all injections are changing

5120 - Oxygen (Lambda) Sensor B1 S1

P2196 00 [237] - Signal too High (Rich)

After erasing and doing about 300km the error returns, the second problem is uneven idling, shakes the engine and you can hear a two-mass wheel. I started to diagnose the fuel system, there are no filings on the CR pump in the strainer. Fuel pressure on the bar at idling very strange jumps, from 190 bars to 320, the engine shakes two-mass. The mechanic said that you need to replace the bimass because through it rages the parking dose and pressure because the computer tries to adjust the uneven rotation of the engine. It can be like that? I am afraid that I will replace the clutch and the symptoms will remain. On vcds it looks like this:

I have also made dynamic logs, fuel pressure in the entire rev range, probably good, turbo and the rest also look ok:

I also made an overflow test for injections:

You can see that the 2 injections are weak, maybe it crashes oxygen error with info about a rich dose. I am concerned about the idling fuel pressure, can it be the culprit two years or injection? or maybe a valve? Does the overflow test give 100% confidence that the injection is for replacement? What do you recommend to me, where to start? Injections correction are very floating, once on injection is a dose of even -2mg and in a moment can change to + 1mg, and so on almost all injections are changing