Hello

I have a FAAC740 drive with magnetic sensors, a photocell and a remote control. The drive has been operating for two years, but recently at

closing, it stops responding to the magnetic limit switch - it reaches a post and a beech. You have to stop it with a remote control.

I read some of the posts and it seemed the problem was with the reed switch or the magnets.

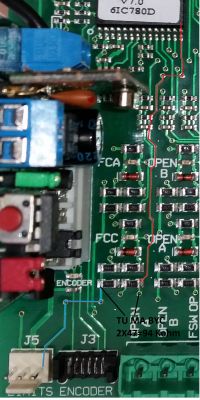

During the tests, I noticed that the FCC LED goes out when opening, but the FCA does not go out when closing.

However, after dismantling and disconnecting the sensor (J5) and checking it with a meter, it turns out that everything is OK: one contact reacts to one magnet, the other to the other. However, when the reed switch is connected to the drive, only the FCC LED goes out and the FCA does not react.

However, I noticed that after removing the reed switch from connector J5, both LEDs are on - should they not go out then?

When I short the middle pin with one of the extreme pins, the FCC goes out, but when I short the middle pin with the other FCA pin, it still lights.

The tile is clean and dry. Logic set to EP, I checked the settings - everything seems to be OK.

The gate also works without any problem.

Does anyone have an idea what could be the reason?

I have a FAAC740 drive with magnetic sensors, a photocell and a remote control. The drive has been operating for two years, but recently at

closing, it stops responding to the magnetic limit switch - it reaches a post and a beech. You have to stop it with a remote control.

I read some of the posts and it seemed the problem was with the reed switch or the magnets.

During the tests, I noticed that the FCC LED goes out when opening, but the FCA does not go out when closing.

However, after dismantling and disconnecting the sensor (J5) and checking it with a meter, it turns out that everything is OK: one contact reacts to one magnet, the other to the other. However, when the reed switch is connected to the drive, only the FCC LED goes out and the FCA does not react.

However, I noticed that after removing the reed switch from connector J5, both LEDs are on - should they not go out then?

When I short the middle pin with one of the extreme pins, the FCC goes out, but when I short the middle pin with the other FCA pin, it still lights.

The tile is clean and dry. Logic set to EP, I checked the settings - everything seems to be OK.

The gate also works without any problem.

Does anyone have an idea what could be the reason?