FAQ

TL;DR: Quigg IK 4000.13 E0 faults often trace to a failed 22 Ω startup resistor; “the integrated circuit VIPer xx … is faulty” can also apply. [Elektroda, TONI_2003, post #19993686]

Why it matters: This FAQ helps DIYers quickly diagnose E0 and power-up faults without needless parts swaps, saving time and money.

Quick Facts

- E0 can appear with unsuitable cookware; swapping pots restored heating in-thread tests. [Elektroda, sebaele22, post #16658716]

- The glass-top thermistor needs thermal grease contact for accurate temperature sensing. [Elektroda, TONI_2003, post #16658986]

- Reported thermistor reading: approx. 112 kΩ at room temperature. [Elektroda, sebaele22, post #16659009]

- Startup/supply resistor noted failing: 22 Ω, 1 W on some boards. [Elektroda, Adam Pluta, post #19989762]

- Long-term fix reported after replacing the VIPer inverter IC and resistor. [Elektroda, Adam Pluta, post #20010149]

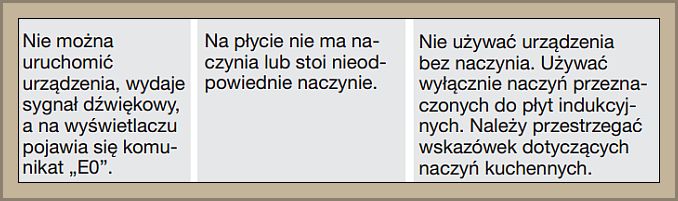

What does error E0 mean on the Quigg IK 4000.13, and how do I clear it?

E0 commonly indicates the hob does not detect a suitable pan. Use a flat, ferromagnetic pot centered on the coil. In the thread, swapping to a different pot cleared E0 and heating resumed. If cookware is fine, check the temperature sensor contact with the glass. Poor contact or dried paste can mislead protection circuits and trigger errors. Clean the pad and reapply thermal grease to the thermistor puck under the glass, then retest with water in the pot. [Elektroda, sebaele22, post #16658716]

Do I need thermal paste on the center temperature sensor?

Yes. That disc-like part is a thermistor that monitors glass temperature. It must conduct heat to the sensor reliably. Apply a thin, even layer of thermal grease where the glass meets the sensor pad. This restores accurate readings and avoids nuisance shutdowns. As one expert put it: “Yes, because it’s a thermistor… Give.” Do not use toothpaste; it dries and insulates. Reassemble carefully to maintain pressure on the sensor. [Elektroda, TONI_2003, post #16658986]

What value should the thermistor read at room temperature?

A user measured about 112 kΩ at room temperature on the IK 4000.13’s sensor. Your exact value may vary with temperature and part tolerance. If the reading is open or far outside this ballpark at room temperature, wiring or the sensor may be faulty. Clean contacts and confirm stable readings while gently warming to see a smooth resistance change. Document readings for future reference. [Elektroda, sebaele22, post #16659009]

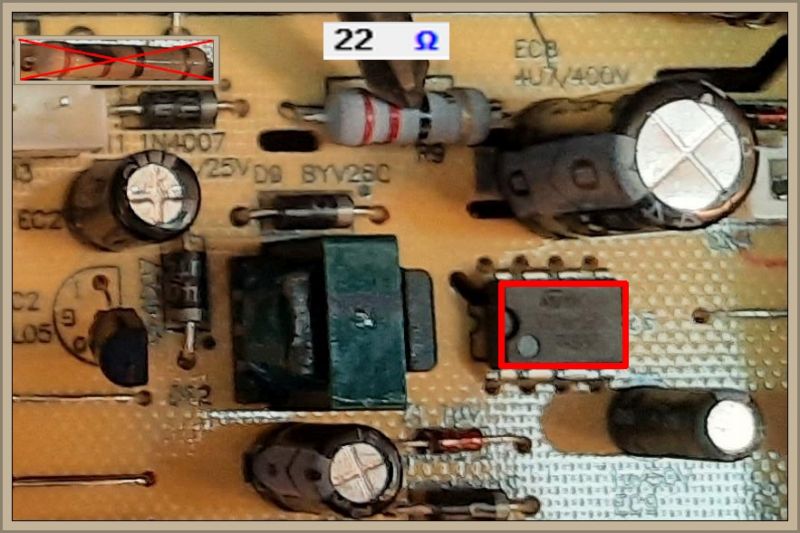

Which resistor commonly fails and causes no-start or E0 symptoms?

The thread documents repeated failures of a 22 Ω, 1 W startup/supply resistor. A burned or drifting resistor can cause boot instability and shutdowns. Replace with the correct flameproof type and verify related supply components. Inspect for heat discoloration around the resistor footprint. After replacement, monitor current draw on first power-up. [Elektroda, Adam Pluta, post #19989762]

I replaced the 22 Ω resistor, but it burned again after a few minutes—what next?

A user reported the hob ran 2–3 minutes, then the resistor failed again. That points to upstream converter issues. The expert advised checking and replacing the VIPer-series inverter IC. Using the correct resistor type matters; wired or incorrect parts overheat. Replace the VIPer IC and the 22 Ω resistor together, then soak-test under load. [Elektroda, TONI_2003, post #19993686]

Did anyone confirm a lasting fix after changing the VIPer IC?

Yes. The poster returned to confirm the hob had been running for days after replacing the VIPer inverter IC as advised. This supports addressing the root-cause in the supply converter, not just the sacrificial resistor. Perform a visual inspection for collateral damage before final assembly. [Elektroda, Adam Pluta, post #20010149]

How do I test cookware compatibility to avoid E0?

Place a small amount of water in a flat-bottom ferromagnetic pot, centered on the zone. If E0 persists, try another pot. In-thread, swapping pots immediately restored operation. If multiple compatible pots still trigger E0, check sensor paste and supply components. Keep the glass clean to aid pan detection. [Elektroda, sebaele22, post #16658716]

What is a VIPer IC in this context?

The VIPer is the hob’s off-line switcher IC used in the low-voltage supply/converter. Failures can overload the 22 Ω startup resistor. The expert specifically flagged the “integrated circuit VIPer xx” as suspect when resistors re-fail. Replace it with the correct variant and verify startup rails. [Elektroda, TONI_2003, post #19993686]

Is the diode-like part near the sensor actually a zener diode?

A user reported a diode-like part with “no value” measured, while the thermistor tested good. The thread does not identify this part conclusively. Without a schematic, confirm part labeling and traces before replacing anything. Document markings and compare with the working side on twin-hob models. [Elektroda, kciuq, post #19894824]

Can I get the board schematic for the Quigg IK 4000.13?

A late-post request asked for the schematic, but none was shared in the thread. For repairs, mirror-measure the good channel on two-burner versions and photograph component codes. Build a partial schematic from high-res photos for future reference. [Elektroda, gdcrni, post #21489809]

Three-step How-To: fixing repeat 22 Ω resistor failures

- Inspect and replace the 22 Ω startup resistor with the correct flameproof spec.

- Replace the VIPer-series inverter IC; check for shorts or cracked solder joints.

- Power up with a series bulb or variac and soak-test under load for 10 minutes.

[Elektroda, TONI_2003, post #19993686]

Is toothpaste acceptable as thermal paste during testing?

A user tried toothpaste and the hob ran temporarily. Toothpaste dries, increases thermal resistance, and risks false readings. Use proper silicone-based thermal grease for stable sensor coupling. Re-clean both surfaces before applying a small, even layer. Recheck E0 behavior with known-good cookware. [Elektroda, sebaele22, post #16659009]

What’s an edge case that can mislead diagnosis?

Using the wrong resistor type or a wired substitute can mask the real fault. The expert flagged a mis-specified 22 Ω part and pointed to the VIPer IC as the underlying issue. Replace both and verify converter rails before concluding the repair. [Elektroda, TONI_2003, post #19993686]

How long did the faulty unit run before failing again?

One report notes the hob ran about 2–3 minutes after the first resistor replacement, then the resistor burned again. Time-to-failure suggests a supply converter fault that heats the startup path. Use thermal imaging or touchless thermometers during soak tests. [Elektroda, Adam Pluta, post #19993034]