Zelmer vacuum cleaner how to connect the soft start?

Vacuum Cleaner Model: missing - sticker torn off

Color of the vacuum cleaner: red

Engine model : S-690

Vacuum Cleaner Power: 1000W

Year of production: January 2006 (date stamped on the engine)

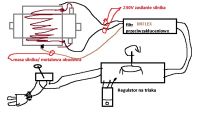

Sketch of the vacuum cleaner scheme:

Soft start cube:

In front of the anti-interference capacitor or behind?

Please help.

Vacuum Cleaner Model: missing - sticker torn off

Color of the vacuum cleaner: red

Engine model : S-690

Vacuum Cleaner Power: 1000W

Year of production: January 2006 (date stamped on the engine)

Sketch of the vacuum cleaner scheme:

Soft start cube:

In front of the anti-interference capacitor or behind?

Please help.