FAQ

TL;DR: 3×400 V is standard in PL networks, and inverters follow "U/f = const" to keep motor flux right. Many drives let you enter a motor’s rated 230 V even on a 400 V input, but model limits apply. [Elektroda, Darom, post #16786821]

Why it matters: This FAQ helps electricians and hobbyists wire 230 V delta motors safely to 400 V systems using the right inverter settings and vocabulary.

Quick Facts

- Inverters rectify AC to DC, then synthesize AC; input and motor voltages are decoupled by the DC link. [Elektroda, Darom, post #16788896]

- Typical parameter menus let you choose a 3×230 V or 3×400 V motor profile. [Elektroda, Darom, post #16812518]

- Speed is commanded by frequency; voltage scales with it per the U/f rule. [Elektroda, Anonymous, post #16786603]

- The “87 Hz technique” is a known method to extend speed with correct voltage utilization. [Elektroda, djlukas, post #16791757]

- A 230/400 V motor in delta on 400 V is unsafe without the right drive setup. [Elektroda, Anonymous, post #16786866]

How does an inverter’s input relate to its motor output voltage?

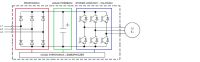

The drive first rectifies the input to DC, then inverts it to variable AC. Because of this DC link, input voltage and motor voltage are not one-to-one. The motor’s voltage and frequency come from drive settings and the speed command, not directly from the mains. [Elektroda, Darom, post #16788896]

Can I run a 230 V delta motor from a 3×400 V supply using a VFD?

Often yes, if the VFD supports entering a 230 V rated motor and limits its output accordingly. Many drives allow selecting a 3×230 V motor profile even when the input is 3×400 V. Check the model’s motor voltage range before wiring. [Elektroda, Darom, post #16812518]

Is it safe to set 230 V, 50 Hz on a VFD that’s fed with 400 VAC?

Not always. Some drives cannot deliver a reduced 230 V line-to-line with a 400 VAC input. Treat a simple "set 230 V" on a 400 V–fed drive with caution unless the model explicitly supports it. [Elektroda, Krzysztof Kamienski, post #16790795]

What does U/f control mean in practice?

U/f control keeps the voltage-to-frequency ratio constant to maintain magnetic flux. As frequency rises, the drive raises voltage proportionally; as frequency falls, it reduces voltage to avoid overfluxing and excess current. "U/f = const." [Elektroda, Anonymous, post #16786603]

Will lowering frequency simply slow the motor?

Yes. The inverter’s frequency setpoint dictates motor speed, while voltage follows per settings. The drive synthesizes an AC waveform from the DC bus to match the requested speed and torque. [Elektroda, Darom, post #16788896]

What is the 87 Hz technique on VFDs?

It’s a setup where a motor intended for 400 V star is connected delta and driven up to about 87 Hz so the winding sees correct voltage per U/f. It extends the constant-power range when the drive supports it. [Elektroda, djlukas, post #16791757]

Can a 230/400 V nameplate motor be wired delta on 400 V directly?

No. A 230/400 V motor in delta expects 230 V line-to-line. Applying 400 V delta overvolts the windings and risks damage. Use a suitable VFD profile or change connection to star as appropriate. [Elektroda, Anonymous, post #16786866]

Do some single‑phase 230 V drives output near 400 V three‑phase?

Yes, there are cases where a 1‑phase 230 V–fed inverter runs a 400 V star motor, but it stresses the system if the DC bus is marginal. Treat this as a constraint case rather than normal operation. [Elektroda, jaro33, post #16802675]

What are voltage‑doubler VFDs and where are they used?

Some drives include voltage doublers that boost low mains (e.g., 120 VAC) to run 3×220 VAC motors. They are common in the USA and avoid external transformers. "Very popular in the USA." [Elektroda, Krzysztof Kamienski, post #16802868]

How do I configure a VFD for a 230 V motor on a 400 V system?

- In motor parameters, select a 3×230 V motor profile and enter nameplate data.

- Set base frequency to 50 Hz and confirm U/f curve matches the motor.

- Test no‑load, then tune ramps and protections.

Many drives provide both 3×230 V and 3×400 V options. [Elektroda, Darom, post #16812518]

Does U/f control also help limit current at low frequency?

Yes. Reducing frequency lowers winding impedance; keeping U/f constant prevents overfluxing and excessive current. This is a key reason drives tie voltage to frequency in scalar control modes. [Elektroda, Anonymous, post #16786866]

What is the DC bus (link) inside a VFD?

It’s the internal DC stage after rectification. The inverter section chops this DC to create variable‑frequency, variable‑voltage AC for the motor. Because of this, the motor sees what the drive commands, not raw mains. [Elektroda, Darom, post #16788896]

Any real‑world example of selectable motor voltage in a VFD menu?

Yes. One cited drive can be ordered for 230 V or 3×400 V input, and its menu lets you choose a 3×230 V or 3×400 V motor. Enter the motor’s rated data during commissioning. [Elektroda, Darom, post #16812518]

What failure should I watch for with higher motor voltages?

Some inverters lack enough DC‑bus voltage to reach a true 400 V output. In that edge case, both motor and drive can run hot if pushed. Plan for the drive’s bus capability. [Elektroda, jaro33, post #16802675]

Is 3×400 V really the standard in Poland?

Yes. The thread explicitly states a 3×400 V installation is standard, which informs how users size and set their VFDs and motor connections. [Elektroda, Darom, post #16786821]