Hello,

Well, I have a problem with the turbine in Octavia 1 1.9 TDI 130 ASZ.

At faster speeds, 150km in 5th gear, 180km in 6th gear, error 17964 charges pressure control crashes.

The same happens when starting quickly and then in 3rd gear at 3.5 thousand revolutions.

I replaced the N75 valve, correctly connected because the first time there was no power. Tubes are now connected according to the ASZ diagram in the label.

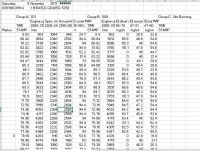

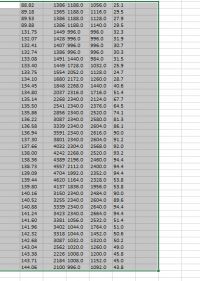

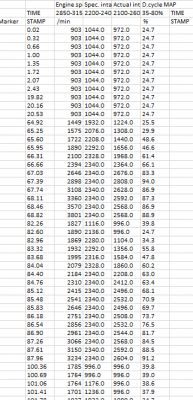

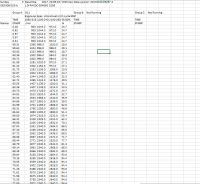

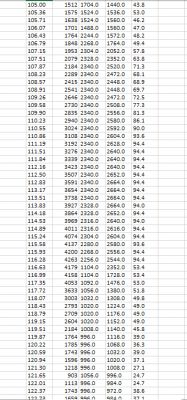

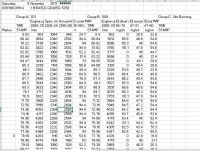

Logs from 011

The car pulls from 1800 to the end like furious But then notlauf. At the start you can feel it from 1700 sudden "kick" and then there is fire.

Vacuum hoses checked, all tight, functional.

Pear tested on BS 011. I checked in the channel under the samhodhod pear moves about 2cm, without slowing down.

Can the pear stutter at higher speeds or is it rather refreshing VTG?

Where can the cause lie? Thanks in advance.

greetings

Well, I have a problem with the turbine in Octavia 1 1.9 TDI 130 ASZ.

At faster speeds, 150km in 5th gear, 180km in 6th gear, error 17964 charges pressure control crashes.

The same happens when starting quickly and then in 3rd gear at 3.5 thousand revolutions.

I replaced the N75 valve, correctly connected because the first time there was no power. Tubes are now connected according to the ASZ diagram in the label.

Logs from 011

The car pulls from 1800 to the end like furious But then notlauf. At the start you can feel it from 1700 sudden "kick" and then there is fire.

Vacuum hoses checked, all tight, functional.

Pear tested on BS 011. I checked in the channel under the samhodhod pear moves about 2cm, without slowing down.

Can the pear stutter at higher speeds or is it rather refreshing VTG?

Where can the cause lie? Thanks in advance.

greetings